Cod. 710.0103.01.00 Rev2A – 11.2012

16 - 111

7.0 TROUBLESHOOTING

SYMPTOM

POSSIBLE ORIGIN

SOLUTION

A) Temperature

shown in display

higher than the preset

value.

•

High compressed air inlet temperature.

•

High compressed air flow.

•

High ambient temperature.

•

Fouler refrigerant condenser.

•

Low refrigerant charge.

•

Phases connected incorrectly.

•

Faulty refrigerant compressor.

•

Faulty fan.

•

Faulty fan pressure switch or thermostat.

•

Faulty electronic controller

•

Reduce air temperature to within design limits.

•

Reduce air flow to within design limits.

•

Increase ventilation rate of installation area.

•

Clean condenser.

•

Locate and repair leak and re-charge.

•

Connect the phases correctly.

•

Replace item.

•

Replace item.

•

Replace item.

•

Replace item.

B) Excessive air

pressure drop across

dryer.

•

Inlet / outlet piping reversed.

•

Temperature probe out of well.

•

Faulty refrigerant solenoid valve.

•

Ambient temperature below freezing.

•

Obstruction in air circuit.

•

Air by – pass valve closed.

•

Connect properly.

•

Re-install.

•

Replace item.

•

Install dryer in heated space.

•

Locate and remove blockage.

•

Open valve.

C) Water present in air

downstream of dryer.

•

Condensate drain strainer fouled.

•

Faulty condensate drainer.

•

Faulty electronic controller.

•

High dew – point temperature.

•

Air by – pass valve open.

•

Clean strainer.

•

Replace item.

•

Replace item.

•

See Symptom #A above.

•

Close valve.

8.0 CONDENSATE DRAIN

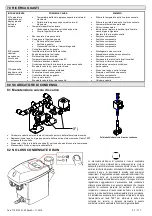

8.1 Drain valve maintenance

•

Close the ball valve located on the filter/stop installed at the drain trap inlet.

•

Depressurize the trap by pushing the TEST button on the control panel.

•

Unscrew the plug in the end of the filter/stop to access the filter screen (F) and

clean it with a compressed air jet.

•

Reassemble and open filter/stop valve.

Cleaning of the drain solenoid valve

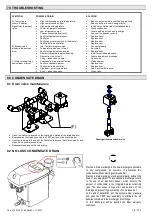

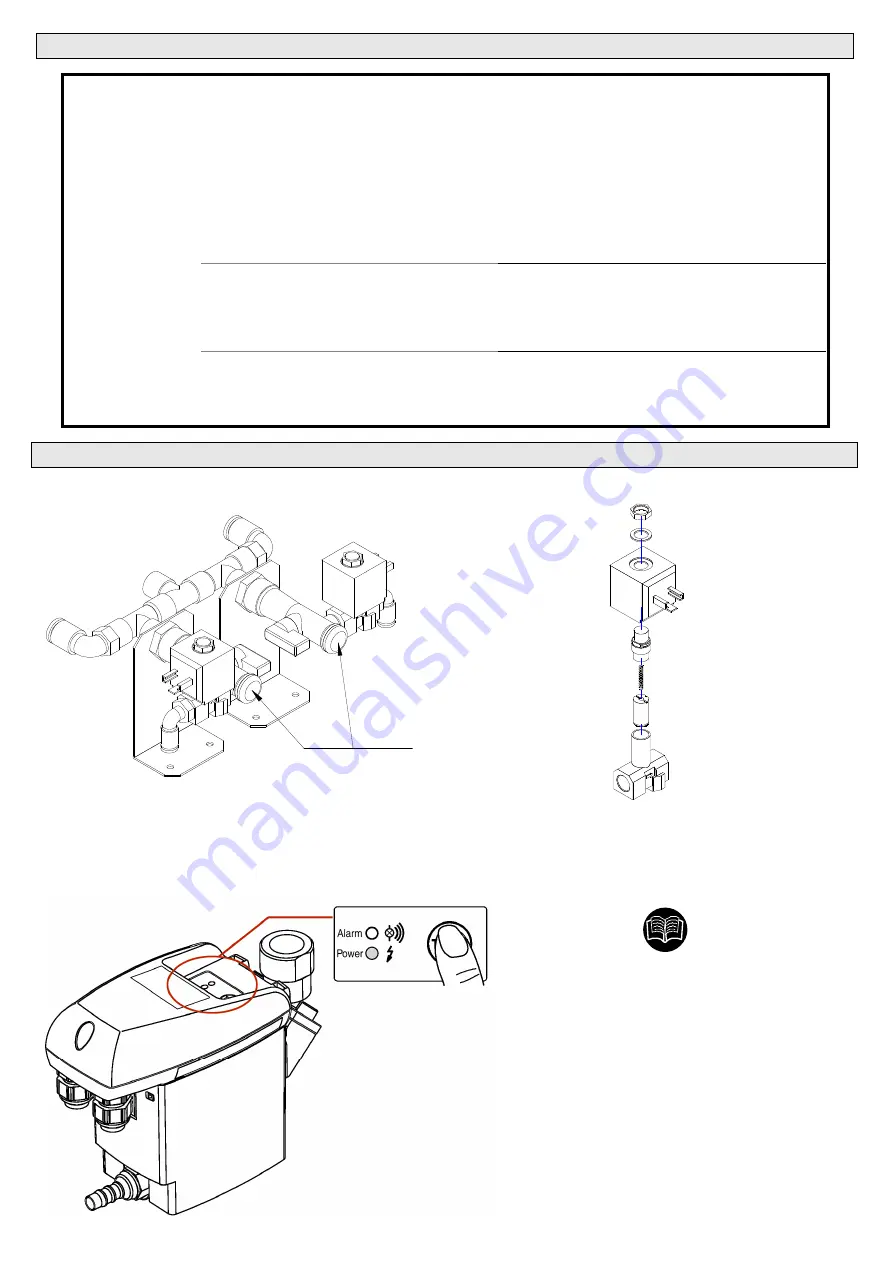

8.2 NO LOSS CONDENSATE DRAIN

Electronic drain discharge is the new discharger applicable

to any compressed air systems. It eliminates the

condensate without wasting compressed air.

Electronic drain discharge starts automatically, without the

need of any adjustment. The condensate discharge occurs

to the use of an electronic sensor, which detects the

amount of condensate in the integrated water collecting

tank. The level sensor drives start and duration of the

drainage, so preventing any wasting of compressed air.

At the end of installation, put the system under pressure

and push the TEST key repeatedly to eliminate the air

bubbles contained in the discharger inlet fittings.

To this discharger will be applied the Beko warranty

conditions.

(F)

Summary of Contents for ED 1300

Page 2: ...1 113 ...

Page 4: ...5 113 ...

Page 115: ...Cod 710 0103 01 00 Rev2A 11 2012 111 111 SLI VB SC FF VG IM TH G VT ...

Page 116: ......