Cod. 710.0103.01.00 Rev2A – 11.2012

17 - 111

The electronic drain discharge is supplied completely

with an output configured as remote signalling alarm.

Proceed as follows to activate a remote alarm

output:

1.The User must provide a signaller in compliance to

output relay electrical features (solenoid coil, light

bulb, acoustic signaller, ...).

2. Disconnect the dryer from electrical feeding and

open the electrical box.

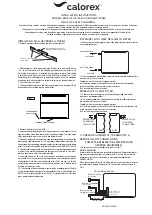

3. Connect the signaller on “BEKO DISCHARGER

ALARM” terminal blocks (See electric wiring

diagram).

Alarm Output relays electric features:

Voltage

<250Vac

max. current

<1,0A

Activation of the above function is on User’s discretion. The User will purchase all necessary

installation material by himself. Any operation which needs access to the dryer must be carried out

by qualified personnel.

8.3 Maintenance and malfunctioning treatment

Should the discharger not operate correctly, try to act on the TEST key to clean the mesh

filter.

Never remove the discharger body. Should the malfunctioning persist, contact our Customer

Service.

9.0 DECOMMISSIONING

In case of necessity, decommission the machine and the relevant packaging in compliance with the

rules locally in force.

Pay particular attention to the refrigerant, as it contains part of the refrigerating compressor lubricating

oil.

Always contact a waste disposal and recycling facility.

10.0 SAFETY REQUIREMENTS

In case of Freon gas leak, it’s important to keep in mind the following risks / damages to goods and people.

FREON

DANGERS

FIRST AID

R134a

R407C

High concentration can cause asphyxia , lose of consciousness and lose of

mobility.

Low concentration can cause narcotic effects

Move the victim to an uncontaminated zone,

keep him/her warm and call the doctor.

R507

Contact with skin and eyes.

Swallowing is an improbable cause of risk.

Rinse immediately the eyes with water for 15

minutes.

In case of low temperature Freon gas spray

burn sprinkle water for 15 minutes.

11.0 DAILY REGISTER

According to EN 378-1 specification, it’s necessary to keep an updated daily register of the refrigerant system.

The register, freely chosen and filled in by the dryer’s user, must contain the following information:

•

All repairing and maintenance interventions;

•

Freon consumption (new, re-utilized, recycled) and Freon quantities loaded for each maintenance intervention;

•

Test results on Freon gas;

•

Freon origin;

•

Modifications and replacements of system components.

•

Periodical tests results;

•

Significant working periods.

Keep the register in the engine room and/or in other rooms, just to have it put in an accessible place to the person in charge of its maintenance.

Summary of Contents for ED Series

Page 2: ...1 113...

Page 4: ...5 113...

Page 82: ...Cod 710 0103 01 00 Rev2A 11 2012 78 111 RU OMI 1 ON OFF 12...

Page 83: ...Cod 710 0103 01 00 Rev2A 11 2012 79 111 1 0 1 1 OMI IP 42 1 2 1 2 3 4 5 6 7 8 9...

Page 115: ...Cod 710 0103 01 00 Rev2A 11 2012 111 111 SLI VB SC FF VG IM TH G VT...

Page 116: ......