Cod. 710.0138.01.00 Rev04A

– 03.2017

© Copyright 2017 OMI Srl - All rights reserved

11

– 12

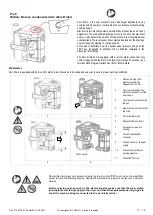

Pic.5

Option: No loss condensate drain (Zero Drain)

Zero Drain is the new electronic drain discharger applicable to any

compressed air systems. It eliminates the condensate without wasting

compressed air.

Electronic drain discharge starts automatically, without the need of any

adjustment. The condensate discharge occurs to the use of an electronic

sensor, which detects the amount of condensate in the integrated water

collecting tank. The level sensor drives start and duration of the drainage,

so preventing any wasting of compressed air.

At the end of installation, put the system under pressure and push the

TEST key repeatedly to eliminate the air bubbles contained in the

discharger inlet fittings.

The Zero Drain unit is equipped with a remote alarm connection (dry

contact, trigged when the drain is in alarm for more than 30 seconds): see

terminal block diagrams (attachment B) for futher details.

Maintenance

Zero Drain is equipped with Service Unit, which is recommended to be changed every year to ensure proper working conditions

.

1.

Disconnect Dryer from

electrical supply and

depressurize to 0 bar.

2.

Unscrew and remove the

electrical connector from the

service unit.

3.

Unscrew 4 screws that holds

the unit.

4.

Remove the Service Unit from

the drain.

5.

Clean the filter mesh.

6.

Replace the Service Unit.

7.

Screw four screws into

housing.

8.

Connect the electrical

connector.

9.

Connect the dryer to power

supply.

10.

Pressurize dryer back to

working pressure.

11.

Press TEST button.

1

2

3

4

Should the discharger not operate correctly, try to act on the TEST key to clean the mesh filter.

Never remove the discharger body. Should the malfunctioning persist, contact our Customer

Service.

Before carrying out any work on the electrical parts, make sure that the main switch

interrupts the electricity supply to the dryer and then affix appropriate warning signs to

avoid the machine being reconnected to the electricity mains!

Filter mesh