Cod. 710.0201.01.00 Rev.01

– 05.2022

© Copyright 2022 OMI Srl - All rights reserved

6 - 11

6

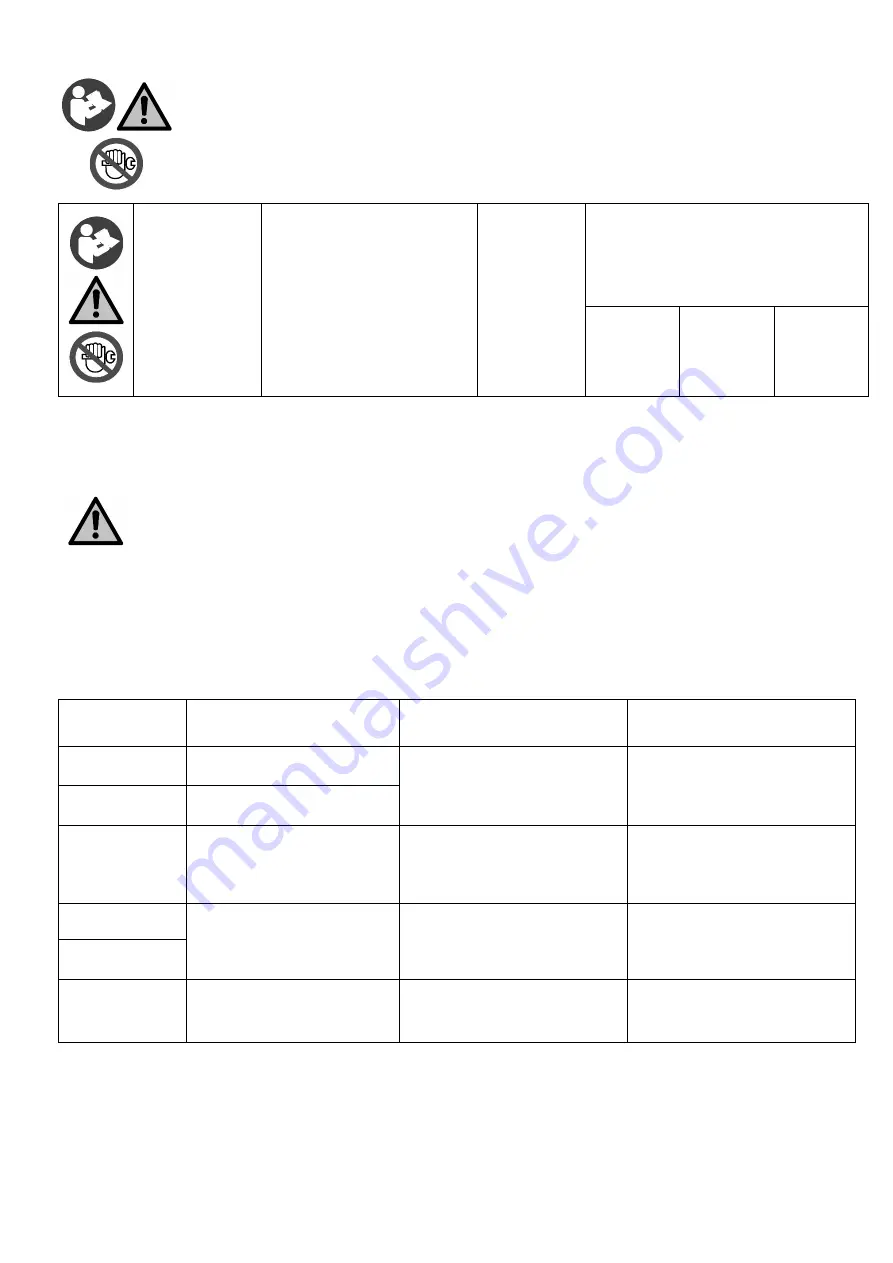

3.1.2 CONDENSATE DISCHARGE PARAMETERS PROGRAMMING

Push the SET key for 10 seconds to enter the parameters configuration menu: the display will show in sequence

the set point value, the code of the first modifiable parameter (C8) and its value).

Only if strictly necessary, use the UP and/or DOWN keys to change the displayed parameter value.

Press the SET key to store the previously changed parameter value or to browse the parameters without

changing them.

15 seconds after the last performed operation, the controller will return automatically to the normal operation

mode.

PARAMETER

DESCRIPTION

RANGE

DEFAULT SET VALUE

C8

Delay between condensate

discharges

1 ÷ 240 (min)

1

C9

Time required for condensate

discharge

1 ÷ 240 (sec)

ED88-108

HP45

ED180-225

HP45

ED270-1200

HP45

1

2

3

NOTE: Changes entered for timing values will be effective only after exiting the programming, while changes to other variables

will be immediately effective.

Please remember that eventual changes to the configuration parameters of the machine could negatively affect its efficiency.

Thus, changes have to be performed by a person familiar with the operation of the dryer.

WARNING FOR USER:IT’S FORBIDDEN TO ATTEMPT TO MODIFY THE OTHER CONFIGURATION PARAMETERS

OF THE ELECTRONIC CONTROLLER WITHOUT AUTHORIZATION AND COLLABORATION OFOMI

’S

AUTHORIZED DISTRIBUTOR.

3.1.3 DISPLAY INDICATIONS

The controller is capable of recognizing certain types of anomalies in the drying circuit. In such cases, a message will blink on the

display, alternated to the current dew point value.

MESSAGE

(BLINKING)

CAUSE

OUTPUTS

ACTIONS

HtA

High dew point value

(delayed alarm)

Alarm output ON

Refrig. Compressor output OFF

Fan output ON

Drain cycle standard

Resettable by switching off the

dryer.

If problem persists call your

localOMI distributor.

Ht2

Very high dew point value

(immediate alarm)

PF1

Interruption or short circuit on the

PTC probe input line

Alarm output ON

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

Resettable by switching off the

dryer. May require replacing the

faulty probe.

If problem persists call your

localOMI distributor.

ESA

The automatic Energy saving

mode activated due to low load

Alarm output OFF

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

No action necessary.

Automatic Reset

ES2

ASt

Activated after repeated alarms

Alarm output ON

Refrig. Compressor output OFF

Fan output ON

Drain cycle standard

Call your localOMI distributor.

Note: PF1 has priority on all other messages.