Curing Printed Garments (Cont’d)

1. Set your heat press to the applicable temperature and adjust the pressure to 1-2 prior to

pressing your printed garment.

2. For best results and if possible, thread your garment onto the heat press. Be careful to not

wrinkle or touch the print as the ink is fresh and can result in smearing the print.

3. Place a curing sheet (silicone or Kraft) on top of your print and then press for the applicable

time.

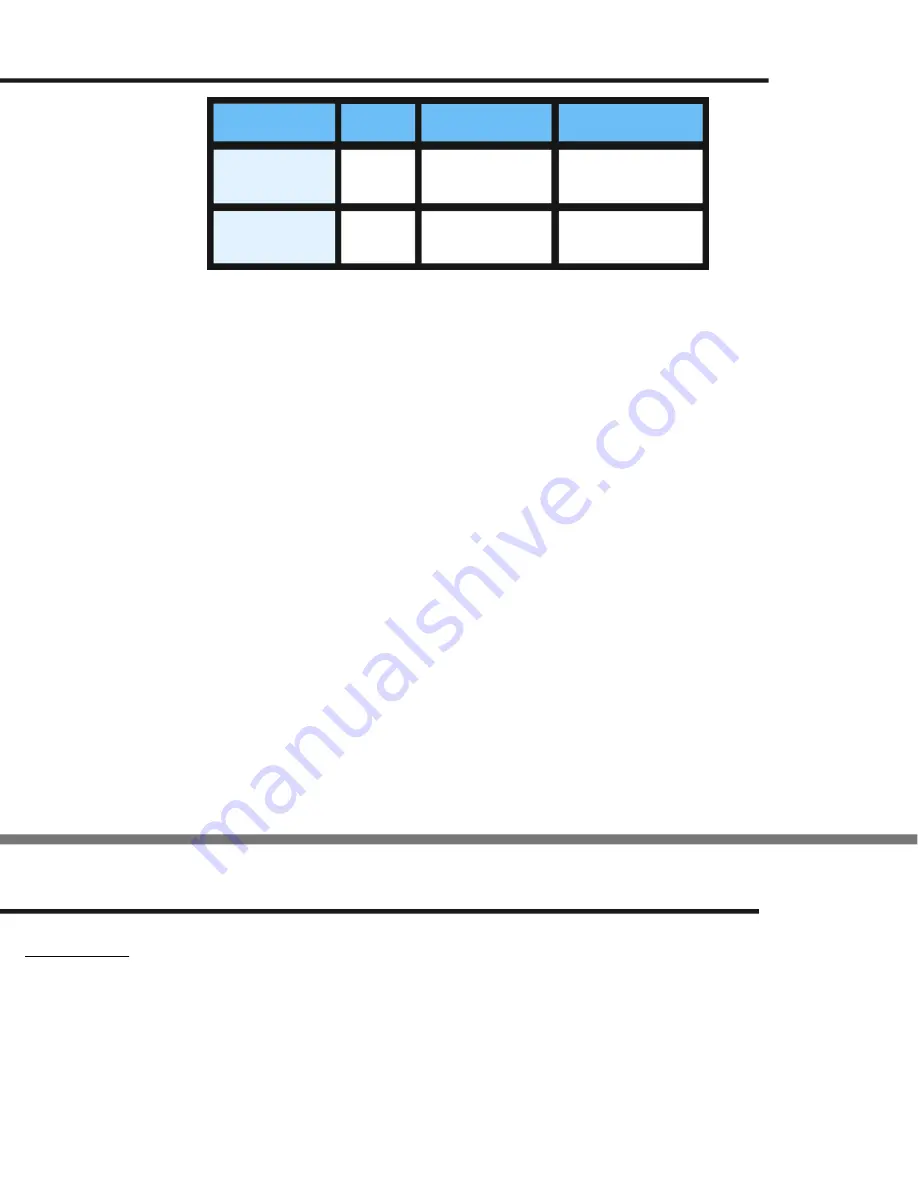

MATERIAL

TEMP

PRESSURE

DRYING TIME

White/Light

Cotton

Black/Dark

Cotton

330°F

345°F

1-2

1-2

45 sec (2x)

90 sec (2x)

IMPORTANT:

PLEASE USE THE ABOVE DATA GUIDELINES AS A STARTING POINT FOR

YOUR CURING PROCESS. ADJUST AS NEEDED TO ACHIEVE THE DESIRED

RESULTS USING YOUR SPECIFIC GARMENT. PLEASE NOTE THAT SETTINGS

AND RESULTS WILL VARY FROM GARMENT TO GARMENT

BASED ON BRAND, QUALITY, COLOR, ETC.

Having issues with pretreating? Need tips? Contact Tech Support:

1-855-373-3538 option 2 • email support@omniprintonline.com • open a ticket at omniprintonline.com/support

DirectRIP Image Adjustment Settings

Fuzziness

The Fuzziness setting is located on your toolbar in the Highlight Generator column. Fuzziness

controls the range of what the RIP considers to be a White highlight in your design when print-

ing. Increasing the Fuzziness will add highlight to lighter colors and off-whites in your design.

Decreasing the Fuzziness will decrease your highlights range and make whites & lighter colors

less bright. Your default setting for fuzziness should be 15, which adjusts the sets highlight to

100% white areas. Adjust as needed to achieve the desired highlight level.

(Continued On The Next Page)

23

Summary of Contents for FREEJET 330TX

Page 1: ...F r e e J e t 3 3 0 T X O f f i c i a l U s e r M a n u a l 2 0 1 9 E d i t i o n ...

Page 2: ......

Page 65: ...62 ...

Page 66: ...63 ...

Page 67: ...64 ...