80-J4866-2 Rev. G

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

3-3

General Wiring and Installation Guidelines

Butt Splicing

Butt Splicing

• Omnitracs recommends Nylon insulated, seamless butt connectors with inspection

windows.

• Heat-shrinkable butt connectors are preferred.

Butt splicing can be done inside and outside the cab or enclosure.

See

Connections Done Inside the Vehicle (Out of the Weather)

Protection for Connections Done Outside the Vehicle

.

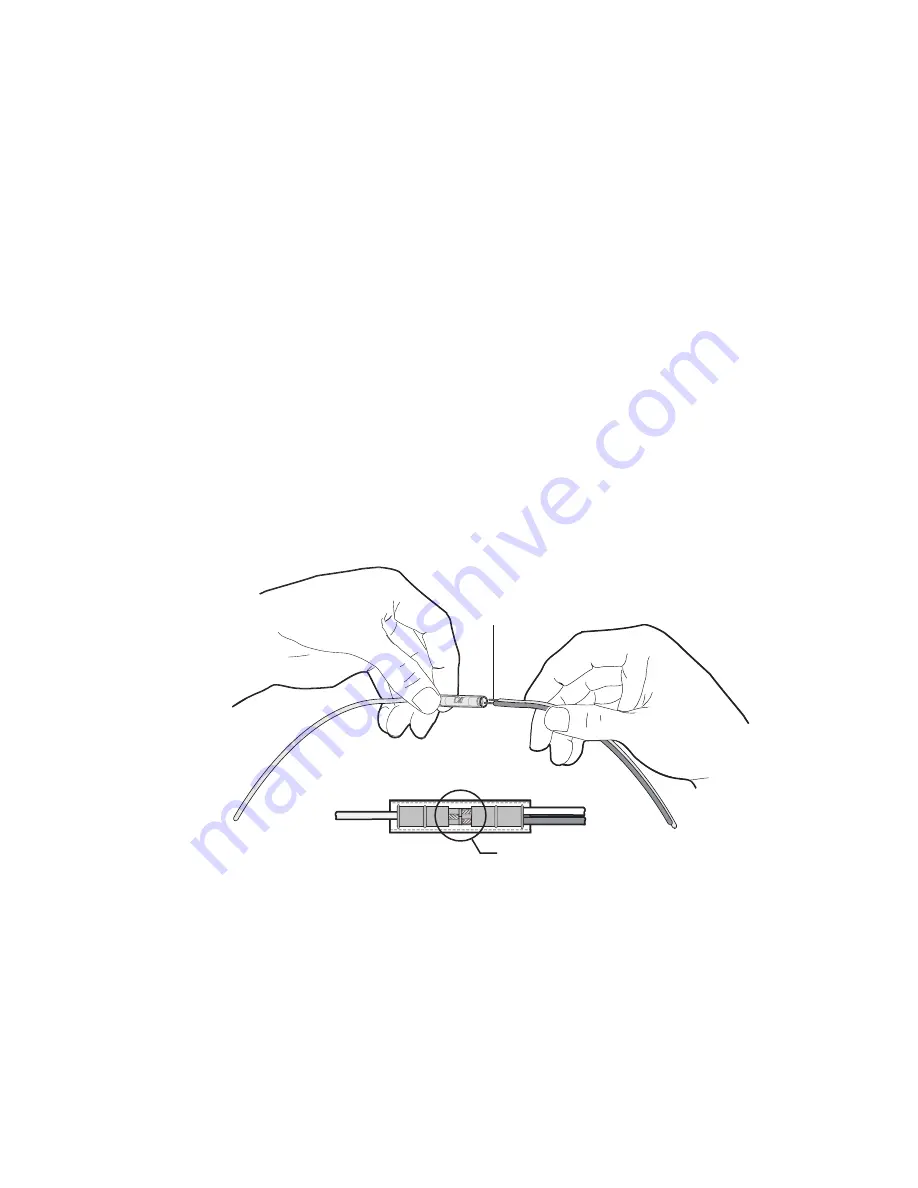

Make sure the size of the butt splice is appropriate for the job. A good butt splice has these

characteristics:

• The ends of the bare wires are visible through an inspection window.

• The ends of the wires “butt” up against the stop.

• The wires are not exposed beyond splice shielding.

• Crimping does not sever or damage the wires or insulation.

Butt Splicing Connections Done Inside the Vehicle (Out of the Weather)

1.

Insert the stripped wires approximately half way into a butt splice, preferably one with

an inspection window for verifying the wire is in the correct position.

2.

Repeat this process for the wire on the opposite end of the butt splice. Once a proper

butt splice is confirmed, it is important to properly crimp the butt splice to hold the

connection.

Push the stripped

wires to the inspection window

of the butt splice

03AAA_272

Butt splice

Inspection window