K8DT-PZ

11

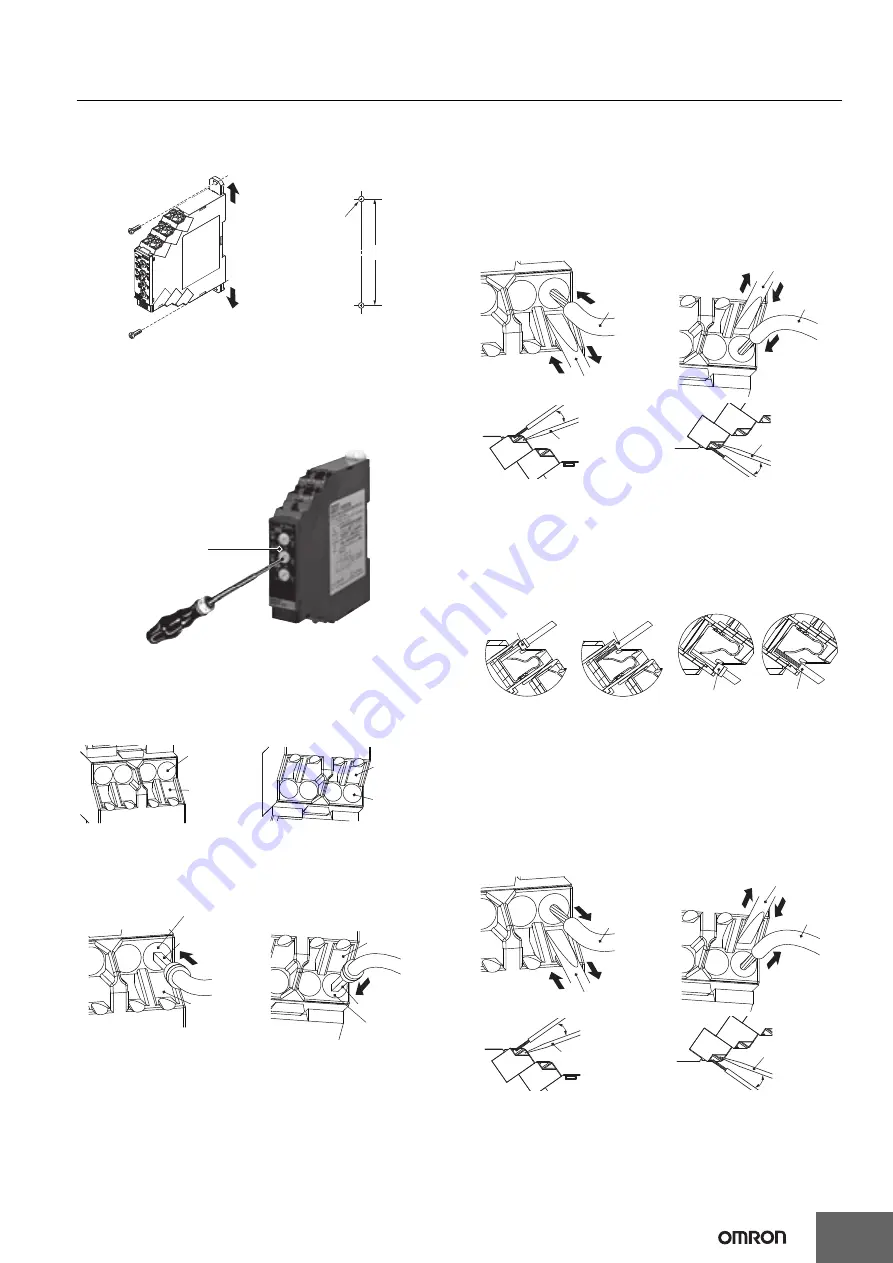

Screw Mounting

1.

Pull out the two hooks on the back of the Relay to the outside until

you hear them click in place.

2.

Insert M3 screws into the hook holes and secure the Relay.

Adjusting the Setting Knobs

• Use a flat-blade screwdriver to adjust the setting knobs. The knobs

have a stopper that prevents them from turning beyond the full right

or left position. Do not force a knob beyond these points.

• To reduce the error in the setting knob, always turn the setting knob

from the minimum setting toward the maximum setting.

Connecting Wires to the Push-In Plus Terminal Block

Part Names of the Terminal Block

Connecting Wires with Ferrules and Solid Wires

Insert the solid wire or ferrule straight into the terminal block until the

end strikes the terminal block.

If a wire is difficult to connect because it is too thin, use a flat-blade

screwdriver in the same way as when connecting stranded wire.

Connecting Stranded Wires

Use the following procedure to connect the wires to the terminal block.

1.

Hold a flat-blade screwdriver at an angle and insert it into the

release hole. The angle should be between 10° and 15°.

If the flat-blade screwdriver is inserted correctly, you will feel the

spring in the release hole respond.

2.

With the screwdriver still inserted into the release hole, insert the

wire into the terminal hole until it strikes the terminal block.

3.

Remove the flat-blade screwdriver from the release hole.

Checking Connections

• After the insertion, pull gently on the wire to make sure that it will

not come off and the wire is securely fastened to the terminal block.

• To prevent short circuits, insert the stripped part of a stranded or

solid wire or the conductor part of a ferrule until it is hidden inside

the terminal insertion hole. (See the following diagram.)

Removing Wires from the Push-In Plus Terminal Block

Use the following procedure to remove wires from the terminal block.

The same method is used to remove stranded wires, solid wires, and

ferrules.

1.

Hold a flat-blade screwdriver at an angle and insert it into the

release hole.

2.

With the flat-blade screwdriver still inserted into the release hole,

remove the wire from the terminal insertion hole.

3.

Remove the flat-blade screwdriver from the release hole.

(1)

(1)

(2)

(2)

Two M3 screw holes or

two 3-dia. holes

108

Mounting Hole Dimensions

Note: 1.

Pull out the hooks to mount

the Relay with screws.

2.

Recommended tightening

torque: 0.5 to 0.6 N·m.

Setting knob

Release hole

Terminal

(Insertion) hole

Release hole

Terminal

(Insertion) hole

<Upper side>

<Lower side>

Ferrule

Release hole

Terminal

(Insertion) hole

Ferrule

Release hole

Terminal

(Insertion) hole

<Upper side>

<Lower side>

Wire

Flat-blade screwdriver

(1)

(3)

(2)

Wire

Flat-blade screwdriver

(1)

(2)

(3)

10 to 15°

10 to 15°

Flat-blade

screwdriver

Flat-blade

screwdriver

<Upper side>

<Lower side>

Ferrule

Ferrule

<Upper side>

<Lower side>

Wire

<Lower side>

Wire

<Upper side>

Wire

Flat-blade screwdriver

(1)

(3)

(2)

Wire

Flat-blade screwdriver

(1)

(2)

(3)

10 to 15°

10 to 15°

Flat-blade

screwdriver

Flat-blade

screwdriver

<Upper side>

<Lower side>