21

Installation

Section 2-2

• Power supply

Applicable power supply specifications are as follows.

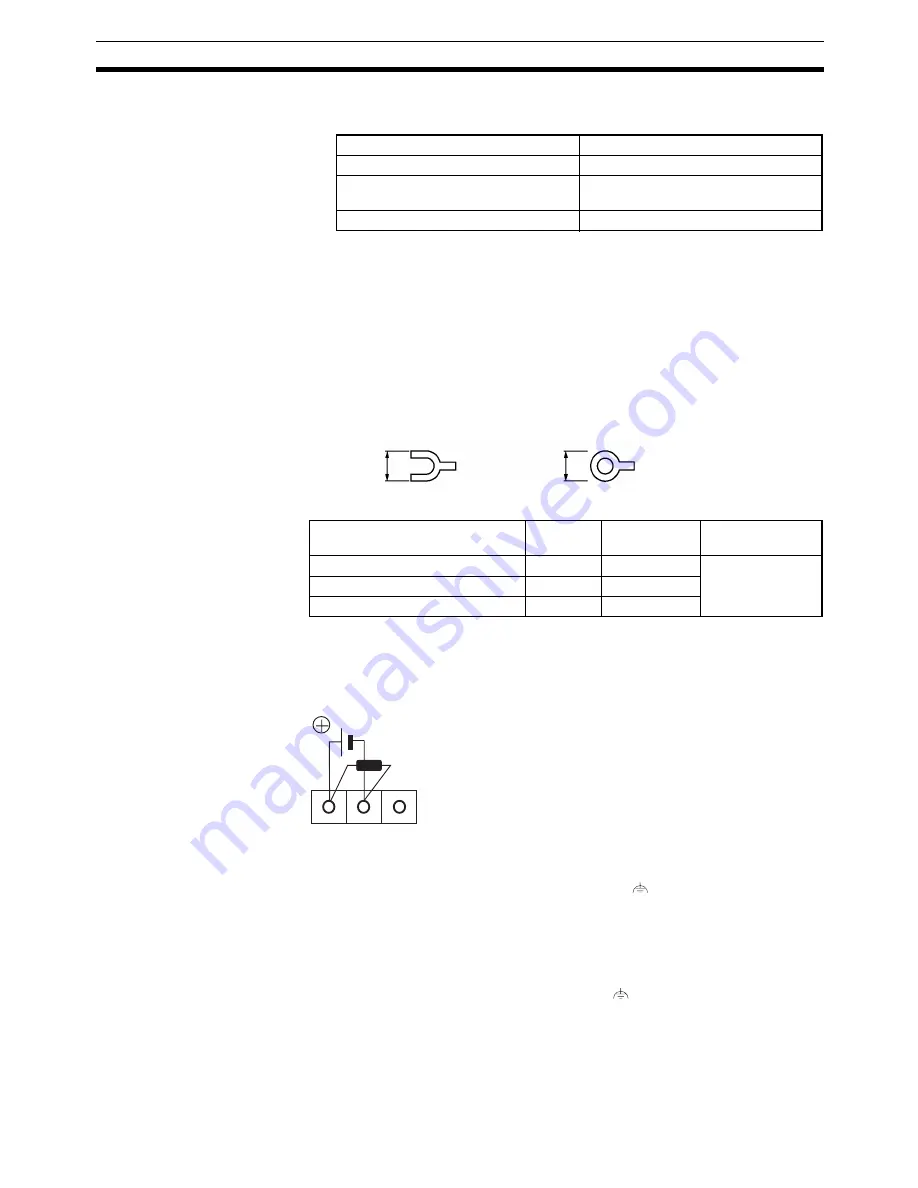

• Parts used for connection

Use crimp terminals to connect the power supply to the power input termi-

nals. Recommended crimp terminals for M3.5 are given below.

!Caution

For the connection to the power supply terminal block, twisted wires of 2 mm

2

or greater cross sectional area and M 3.5 size crimp terminals must be used.

Tighten the screws on the terminal block to a torque of 0.5 N

×

m.

Otherwise fire may occur.

[Recommended terminals]

Note

When surge noise occurs in the DC power supply, connect a Transistor Volt-

age Suppressor (TVS) between the 24-V and 0-VDC terminals.

Recommended TVS model: 1.5KE33CA

Manufacturers: Vishay Intertechnology Inc, STMicroelectronics

2-2-3

Wiring the Ground Wire

The PT is provided with a functional ground (FG:

) terminal.

Wire the FG terminal according to the following conditions.

1.

Ground according to Figure when there is difference in potential between

the PT and host. Do not ground the functional ground of the PT if it is far

from the host and one-point grounding is difficult.

2.

Do not ground the functional ground (FG:

) of the PT if it is mounted to

the same panel as devices that generate noise, such as motors and invert-

ers.

Item

Value

Power supply voltage

24 VDC

Allowable power supply voltage

fluctuation range

20.4 VDC to 26.4 VDC

(24 VDC –15%, +15%)

Power supply capacity

10 W or lower

Maker

Type

(fork type)

Type

(round type)

Applicable Wire

(stranded wire)

Japan Solderless Terminal MFG

2-YS3A

2-3.5

1.04 to 2.63 mm

2

Fuji Terminal

2-YAS3.5

V2-S3.5

Nichifu Terminal

2Y-3.5

2-3.5

Fork type

Round type

7 mm or less

7 mm or less

24 VDC

TVS

Summary of Contents for NT11 - 01-2004

Page 1: ...USER S MANUAL Cat No V084 E1 01 NT11 Programmable Terminal ...

Page 2: ...NT11 Programmable Terminal User s Manual Produced January 2004 ...

Page 3: ...iv ...

Page 5: ...vi ...

Page 13: ...xiv Safety Precautions 3 ...

Page 27: ...14 Before Operating Section 1 6 ...

Page 71: ...58 Connecting a Printer Section 2 8 ...

Page 119: ...106 Daily Report Display History Printing Function Section 4 10 ...

Page 157: ...144 Inspection and Cleaning Section 6 3 ...

Page 162: ...149 Appendix B Dimensions Body NT11 SF121 B EV1 38 2 7 5 218 203 113 98 ...

Page 163: ...150 Dimensions Appendix B ...

Page 165: ...152 Transporting and Storing the NT11 Appendix C ...

Page 183: ...170 Revision History ...

Page 186: ...NT11 Programmable Terminal Cat No V084 E1 01 USER S MANUAL ...