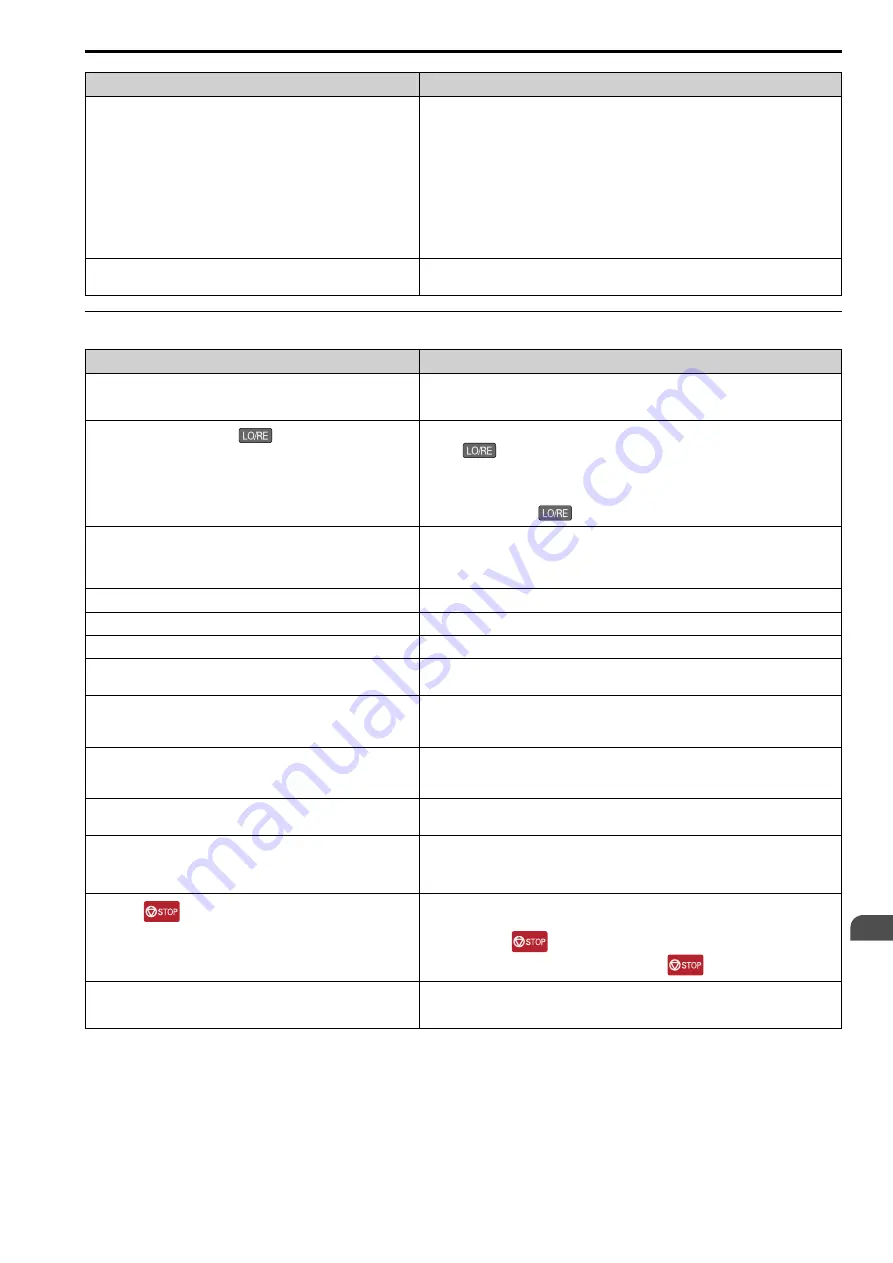

7.10 Troubleshooting Without Fault Display

SIEPCYEUOQ2V01A Q2V Technical Manual

259

Causes

Possible Solutions

An incorrect password was entered in

A1-04 [Password Input]

.

•

Enter the correct password to

A1-04

again.

•

If you forgot the password, set the password again with

A1-04

and

A1-05 [Password Setting]

.

Note:

If the password is set, it will not be possible to change these parameters until the password

matches:

•

A1-01 [Access Level]

•

A1-02 [Control Method]

•

A1-03 [Init Parameters]

•

A1-06 [Macro Preset]

•

A1-07 [Q2pack Enable]

•

A2-01 to A2-32 [MAN1 Param1 to MAN3 Param12]

The drive detected

Uv [Undervoltage]

.

•

View

U1-07 [DC Bus Voltage]

to see the power supply voltage.

•

Examine the main circuit wiring.

◆

The Motor Does Not Rotate After Entering Run Command

Causes

Possible Solutions

The drive is not in Drive Mode.

1.

Make sure that the READY LED on the keypad is on.

2.

If the READY LED is off, push and hold the ESC Key to go back to the frequency reference

screen (the initial screen).

The drive stopped and you pushed

to transfer the Run command

source to the keypad.

Do one of these two:

•

Push

.

•

Re-energize the drive.

Note:

Set

o2-01 = 0 [LO/RE Key Selection of Function = Disabled]

to prevent changing the Run

command source with

.

Auto-Tuning completed.

Push and hold the ESC Key to go back to the frequency reference screen (the initial screen).

Note:

When Auto-Tuning completes, the drive changes to Programming Mode. The drive will not

accept a Run command unless the drive is in Drive Mode.

The drive received a Fast Stop command.

Turn off the fast stop input signal.

The settings for the source that supplies the Run command are incorrect.

Set

b1-02 [Run Comm. Sel 1]

correctly.

The frequency reference source is set incorrectly.

Set

b1-01 [Freq. Ref. Sel. 1]

correctly.

There is defective wiring in the control circuit terminals.

•

Correctly wire the drive control circuit terminals.

•

View

U1-10 [In Terminal Status]

for input terminal status.

The settings for voltage input and current input of the master frequency

reference are incorrect.

Examine these analog input terminal signal level settings:

•

Terminal AI1:

H3-01 [AI1 Signal Level Select]

•

Terminal AI2: DIP switch S1 and

H3-09 [AI2 Signal Level Select]

The selection for the sinking/sourcing mode and the internal/external power

supply is incorrect.

•

For sinking mode, close the circuit between terminals DIC-D24V with a wire jumper.

•

For sourcing mode, close the circuit between terminals DIC-D0V with a wire jumper.

•

For external power supply, remove the wire jumper.

The frequency reference is too low.

•

View

U1-01 [Frequency Reference]

.

•

Increase the frequency reference to a value higher than

E1-09 [Min Output Frequency]

.

The MFAI setting is incorrect.

•

Make sure that the functions set to the MFAI are correct. The frequency reference is 0 when

H3-02, H3-10 = 5 [MFAI Function Select = Freq Gain]

and voltage (current) is not input.

•

Use

U1-13, U1-14 [Terminal AI1 InputLv, Terminal AI2 InputLv]

to make sure that the analog

input values set to terminals AI1 and AI2 are applicable.

You pushed

.

Turn the Run command OFF then ON from an external input.

Note:

When you push

during operation, the drive will ramp to stop. Set

o2-02 = 0 [STOP

Key Selection of Function = Disabled]

to disable the

function.

The 2-wire sequence and 3-wire sequence are set incorrectly.

•

Set one of the parameters

H1-03 to H1-07 [DI3 Function Selection to DI7 Function Selection]

to

5 [3-Wire Seq.]

to enable the 3-wire sequence.

•

If a 2-wire sequence is necessary, make sure that

H1-03 to H1-07 ≠ 5

.

Summary of Contents for Q2V Series

Page 2: ...This Page Intentionally Blank 2 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 12: ...12 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 18: ...i 2 Legal Information 18 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 26: ...1 2 Features and Advantages of Control Methods 26 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 38: ...2 8 Installation Methods 38 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 70: ...3 3 Main Circuit Wiring 70 SIEPCYEUOQ2V01A Q2V Technical Manual Models B006 B012...

Page 102: ...3 17 Motor Application Precautions 102 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 138: ...4 12 Test Run Checklist 138 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 144: ...5 2 European Standards 144 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 145: ...Standards Compliance 5 5 2 European Standards SIEPCYEUOQ2V01A Q2V Technical Manual 145...

Page 146: ...5 2 European Standards 146 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 266: ...7 10 Troubleshooting Without Fault Display 266 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 284: ...8 6 Storage Guidelines 284 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 312: ...10 10 Peripheral Devices and Options 312 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 430: ...11 21 Parameters Changed by PM Motor Code Selection 430 SIEPCYEUOQ2V01A Q2V Technical Manual...

Page 731: ...SIEPCYEUOQ2V01A Q2V Technical Manual 731 Z Z pulse Auto Tuning 125...