7 Advanced Settings

7 - 18

High-function General-purpose Inverter RX2 Series User’s Manual

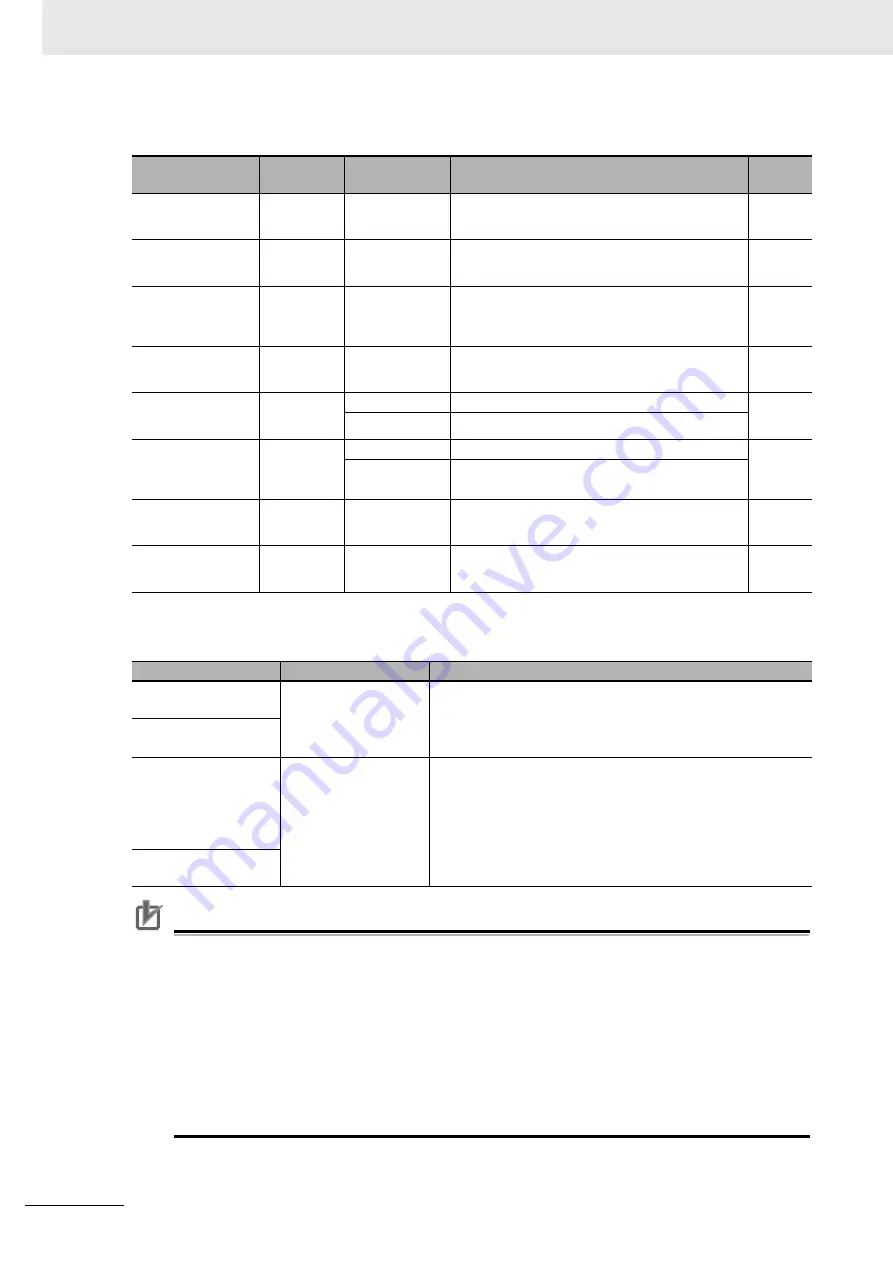

Parameter

In addition to the adjustment of the sensorless vector control, refer to the following description.

Precautions for Correct Use

• Set the carrier speed setting, 1st-motor [bb101] at a value of 2.0 kHz or higher. A set fre-

quency of 1.9 kHz or lower may cause hunting.

• When the revolution of the motor is hindered by such causes as the braking or the motor lock

caused by foreign objects, such hindrance may cause over current or the like. When no such

adjustment as ones mentioned above improves the state, checking the portion around the

motor may sometimes improves it.

• If an application of load results in a great amount of change in the inverter’s output frequency

monitor [dA-01], a function to automatically change the frequencies for the overload limiting

function, the momentary-stop non-stop function, the over voltage suppression function may

work depending upon the settings of the functions.

Item

Parameter

Data

Description

Default

data

Control mode

selection,

1st-motor

[AA121]

09

*1

*1. Cannot be selected if [Ub-03] duty spec selection is 01 (LD) or 00 (VLD).

To use the zero-speed range sensorless vector

control (IM) function.

00

Speed response

for Async.M,

1st-motor

[HA115]

0 to 1000(%)

To adjust the responsiveness of the control.

A larger value enhances the responsiveness.

100

Zero speed area

limit for

Async.M-0SLV,

1st-motor

[HC110]

0 to 100(%)

To limit the current at the start so as not to allow

the rising of the current to rise too high.

80

Boost value at start

for Async.M-0SLV,

1st-motor

[HC112]

0 to 50(%)

To adjust the current command at the start when

the starting torque is not sufficient.

10

Secondary resis-

tance correction,

1st-motor

[HC113]

00

Disabled

00

01

Enabled Requiring a temperature thermistor.

Counter direction

run protection

selection,

1st-motor

[HC114]

00

Disabled

00

01

Enabled Limit the output to prevent the output in

the reverse direction.

Torque current ref-

erence filter time

constant, 1st-motor

[HC120]

0 to 100(ms)

To adjust the filter for the torque current.

2

Speed feedfor-

ward compensa-

tion gain, 1st-motor

[HC121]

0 to 1000(%)

To adjust the feed forward control of the speed

controller.

0

Phenomenon

Estimated cause(s)

Exemplar measures to be taken

Socks occur during the

revolutions at the start. Boost amount is too

large.

• Make an adjustment by decrementing the zero-speed range

limiter [HC110] by 5% each time.

• Make an adjustment by decrementing the zero-speed range

boost at the start [HC112] by 5% each time.

Over current occurs at

the start

The motor cannot pro-

vide enough torque for

the load is too high for

the motor to at the

start.

Boost amount is too

small.

Make an adjustment by incrementing the zero-speed range

boost at the start [HC112] by 5% each time.

Acceleration is not

possible.

Summary of Contents for RX - 2

Page 1: ...High function General purpose Inverter RX2 Series User s Manual I620 E1 01 3G3RX2...

Page 54: ...1 Overview 1 22 High function General purpose Inverter RX2 Series User s Manual...

Page 136: ...2 Design 2 82 High function General purpose Inverter RX2 Series User s Manual...

Page 592: ...8 Applied Settings 8 192 High function General purpose Inverter RX2 Series User s Manual...

Page 754: ...11 Options 11 56 High function General purpose Inverter RX2 Series User s Manual...

Page 794: ...12 Troubleshooting 12 40 High function General purpose Inverter RX2 Series User s Manual...

Page 919: ......