8 Applied Settings

8 - 100

High-function General-purpose Inverter RX2 Series User’s Manual

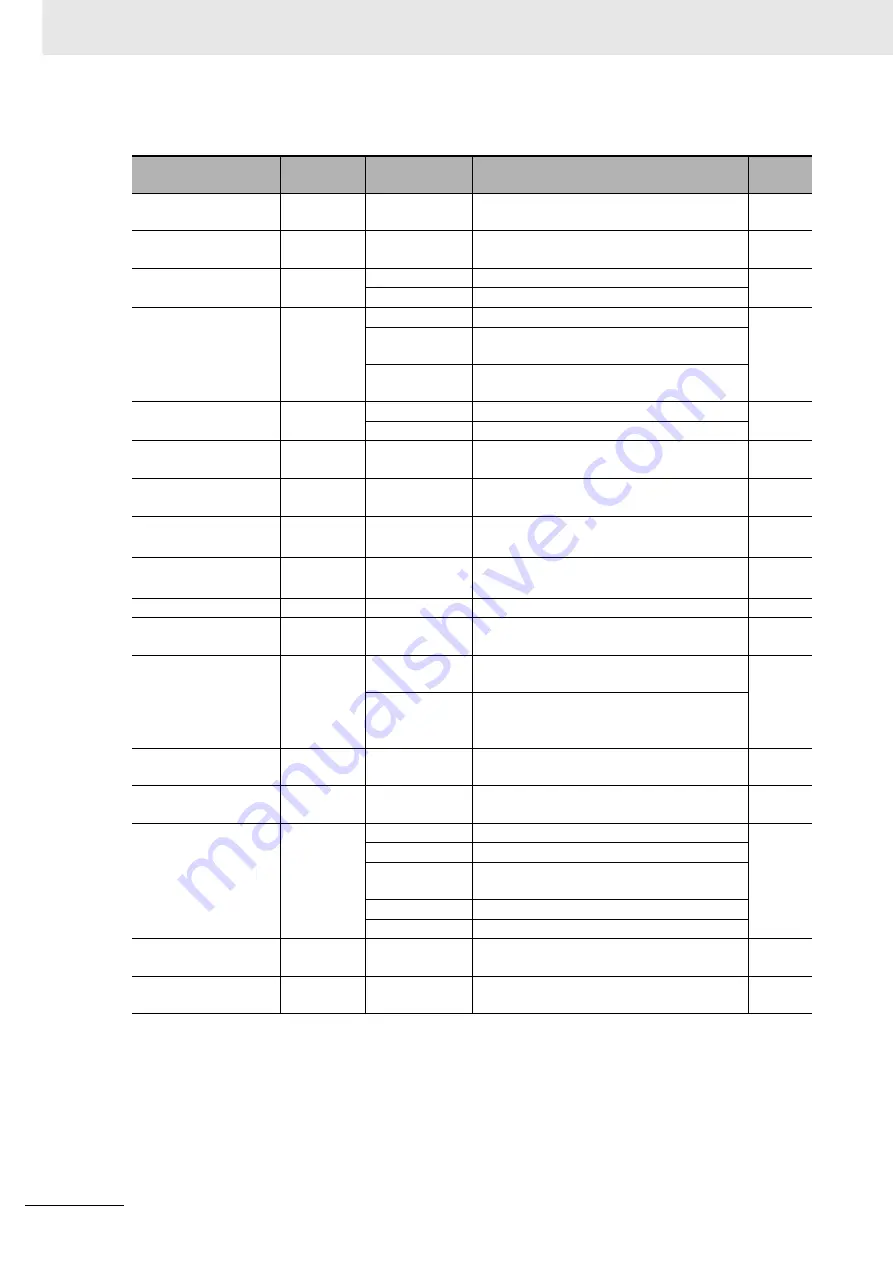

Setting Items for the Pulse Train Position Control

Item

Parameter

Data

Description

Default

data

Control mode

selection, 1st-motor

[AA121]

10

Vector control with sensor

00

Vector control mode

selection, 1st-motor

[AA123]

01

Pulse train position control mode

00

Pulse train detection

object selection

[ob-10]

00

Pulse train frequency command

00

01

Pulse train position command

Mode selection of

pulse train input

[ob-11]

00

MD0: 90° phase difference pulse train

01

01

MD1: Forward/reverse rotation c

pulse train

02

MD2: Forward rotation pulse train + reverse

rotation pulse train

Electronic gear setting

point selection

[AE-01]

00

FB: Feedback side

00

01

REF: Command side

Electronic gear ratio

numerator

[AE-02]

1 to 9999

Numerator of th electronic gear

1

Electronic gear ratio

denominator

[AE-03]

1 to 9999

Denominator of th electronic gear

1

Position feed-forward

gain setting

*1

*1. It is recommended to start position control feedforward gain adjustment with AE-06 set to 2.00. To reduce the

position deviation between the main and sub motors, increase the feedforward gain. If motor hunting occurs,

reduce the feedforward gain.

[AE-06]

0.00 to 655.35

Position feed forward gain.

0.00

Position loop gain set-

ting

*2

*2. It is recommended to start position loop gain adjustment with AE-07 set to 2.00. To increase the positioning

accuracy and the holding power, increase the position loop gain. If the position loop gain is set too high and

causes hunting, decrease the position loop gain.

[AE-07]

0.00 to 100.00

Position loop gain.

0.50

Position bias setting

[AE-08]

-2048 to 2048

Set the bias value of the position.

0

Add frequency setting,

1st-motor

[AA106]

-590.00 to

590.00(Hz)

Frequency added when the [ADD] terminal

is turned on.

0.00

Position deviation

error mode selection

[bb-85]

00

The excessive position deviation signal

[PDD] is output.

00

01

The output of the excessive position devia-

tion signal [PDD] and the position deviation

error [E106] cause a trip.

Position deviation

error detection level

[bb-86]

0 to 65535

(×100pls)

The level for deciding an abnormal position

deviation.

4096

Position deviation

error detection time

[bb-87]

0.0 to 5.0(s)

Set the time until [PDD] is outputted or an

error occurs.

0.5

Selecting the input ter-

minal

[CA-01] to

[CA-11]

014

ADD: Set speed addition

-

072

PCLR: Position deviation clear

073

STAT: Input permission of the pulse train

position command

074

PUP: Adding the position bias

075

PDN: Subtracting the position bias

Selecting the output

terminal

[CC-01] to

[CC-07]

042

PDD: Excessive position deviation signal

-

Pulse train position

deviation monitor

[dA-26]

-2147483647 to

2147483647

Displays the position deviation for the posi-

tion command and position feedback.

-

Summary of Contents for RX - 2

Page 1: ...High function General purpose Inverter RX2 Series User s Manual I620 E1 01 3G3RX2...

Page 54: ...1 Overview 1 22 High function General purpose Inverter RX2 Series User s Manual...

Page 136: ...2 Design 2 82 High function General purpose Inverter RX2 Series User s Manual...

Page 592: ...8 Applied Settings 8 192 High function General purpose Inverter RX2 Series User s Manual...

Page 754: ...11 Options 11 56 High function General purpose Inverter RX2 Series User s Manual...

Page 794: ...12 Troubleshooting 12 40 High function General purpose Inverter RX2 Series User s Manual...

Page 919: ......