Chapter 7: Maintenance

This chapter provides information about maintaining the robot.

During any maintenance-related activities, care must be taken involving AC power lockout. It

is your responsibility to make sure that you observe the following:

l

Lockout/ tagout power to the robot and related equipment.

l

Make sure that the robot cannot be energized during maintenance, as mandated by

Clause 5.2.4 of ISO 10218-1.

7.1 Periodic Maintenance

This section lists when to perform periodic maintenance on your robot and the steps for check-

ing each item to inspect.

NOTE:

Additional maintenance may be necessary for IP54/65 and Cleanroom

robot options. Refer to IP54/65 Option Considerations on page 129 and Clean-

room Option Considerations on page 131 for more information.

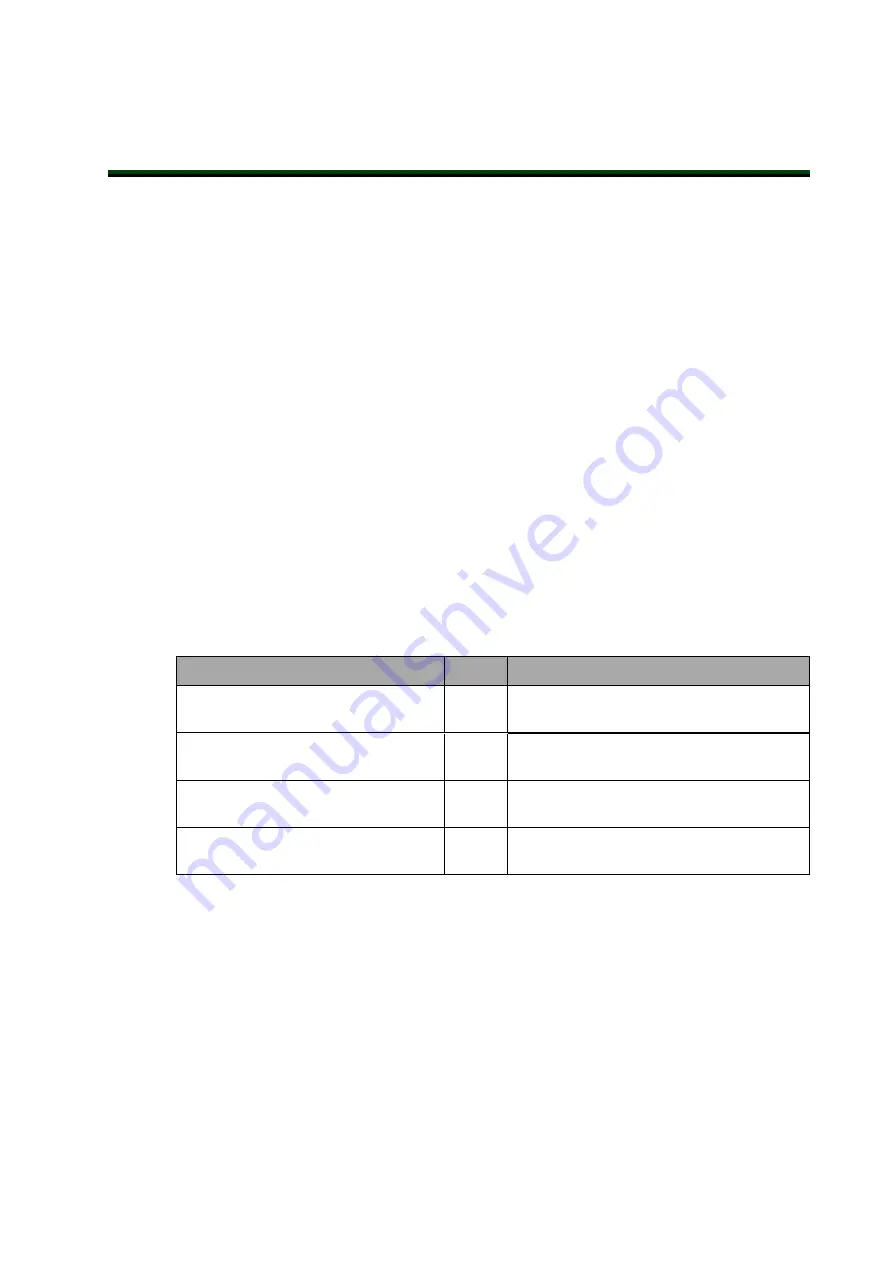

Periodic Maintenance Schedule

The following table gives a summary of the periodic maintenance procedures and guidelines

on frequency.

Table 7-1. Inspection and Maintenance

Item to Inspect

Period

Reference

Check E-Stop, enable and key

switches, and barrier interlocks

6

months

Checking Safety Systems on page 97

Check robot mounting bolts

6

months

Refer to Checking Robot Mounting Bolts

and Cover Plates on page 98

Check Safety Labels

1 week

Refer to Checking Safety and Warning

Labels on page 98

Replace encoder battery

2 to 4

years

Replacing the Encoder Batteries on page 99

NOTE:

The frequency of these procedures will depend on the particular system,

its operating environment, and amount of usage. Use the times in this table as

guidelines and modify the schedule as needed.

Checking Safety Systems

Use the following steps to check all robot safety devices that may be present in the system.

These tests should be done every six months.

IMPORTANT:

Operating any of the following safety devices should disable

robot high power.

21861-000 Rev A

Viper 650 and 850 Robot with EtherCAT

97