XW5T

17

Safety Precautions

Warning Indications

• Do not drop the Terminal Block.

Terminal Block functionality may be inhibited.

• Do not exceed the ratings. Doing so may damage or burn out the

Terminal Block.

• Mount the Terminal Blocks on a DIN Track and secure both ends

with Stoppers.

• Do not use the Terminal Block in locations where toxic gases, such

as H

2

S, SO

2

, NH

3

, HNO

3

, and Cl

2

, may be present, or in locations

subject to high temperature or humidity. Doing so may damage the

Terminal Block due to contact failure or corrosion.

• Do not use the Terminal Block submersed in oil or water, or in

locations continuously subject to splashes of oil or water. Doing so

may result in oil or water entering and damaging the Terminal

Block.

• Do not use or keep the Terminal Block under the following

conditions:

• Subject to severe temperature changes.

• Subject to high humidity or condensation.

• Subject to severe vibration or shock.

• Where direct rays of the sun strike.

• Where sea breeze may be present.

• Do not wire anything to the release holes.

• Do not tilt or twist a flat-blade screwdriver while it is inserted into a

release hole on the terminal block. The terminal block may be

damaged.

• Insert a flat-blade screwdriver into the release holes at an angle.

The terminal block may be damaged if you insert the screwdriver

straight in.

• Do not allow the flat-blade screwdriver to fall out while it is inserted

into a release hole.

• Do not bend a wire past its natural bending radius or pull on it with

excessive force.

Doing so may cause the wire disconnection. Do not place

excessive force on a Terminal Block. Doing so may damage or

deform the Terminal Block and result in contact failure.

• Do not insert more than one wire into each terminal insertion hole.

• If you mount more than one Terminal Block, mount them so that the

conductive parts of adjacent Terminal Blocks are facing in the

same direction. If they face in different directions, short circuits

may occur between adjacent Terminal Blocks.

• To prevent wire materials from smoking or igniting, confirm wire

ratings and use the wiring materials given in the following table.

1. Precautions for Correct Use

• Always mount End Covers to the following locations when you use

Terminal Blocks.

• Exposed metal surface of the last Terminal Block

• Any Terminal Block that is next to a different shape of Terminal

Block

There is a risk of electric shock if End Covers are not used.

• When you wire the Terminal Block, do not subject it or the wires to

stress. Secure the wires so that they do not resonate with

vibrations from the facilities in installation conditions.

• Always turn OFF the power supply before wiring. Electrical shock

may occur.

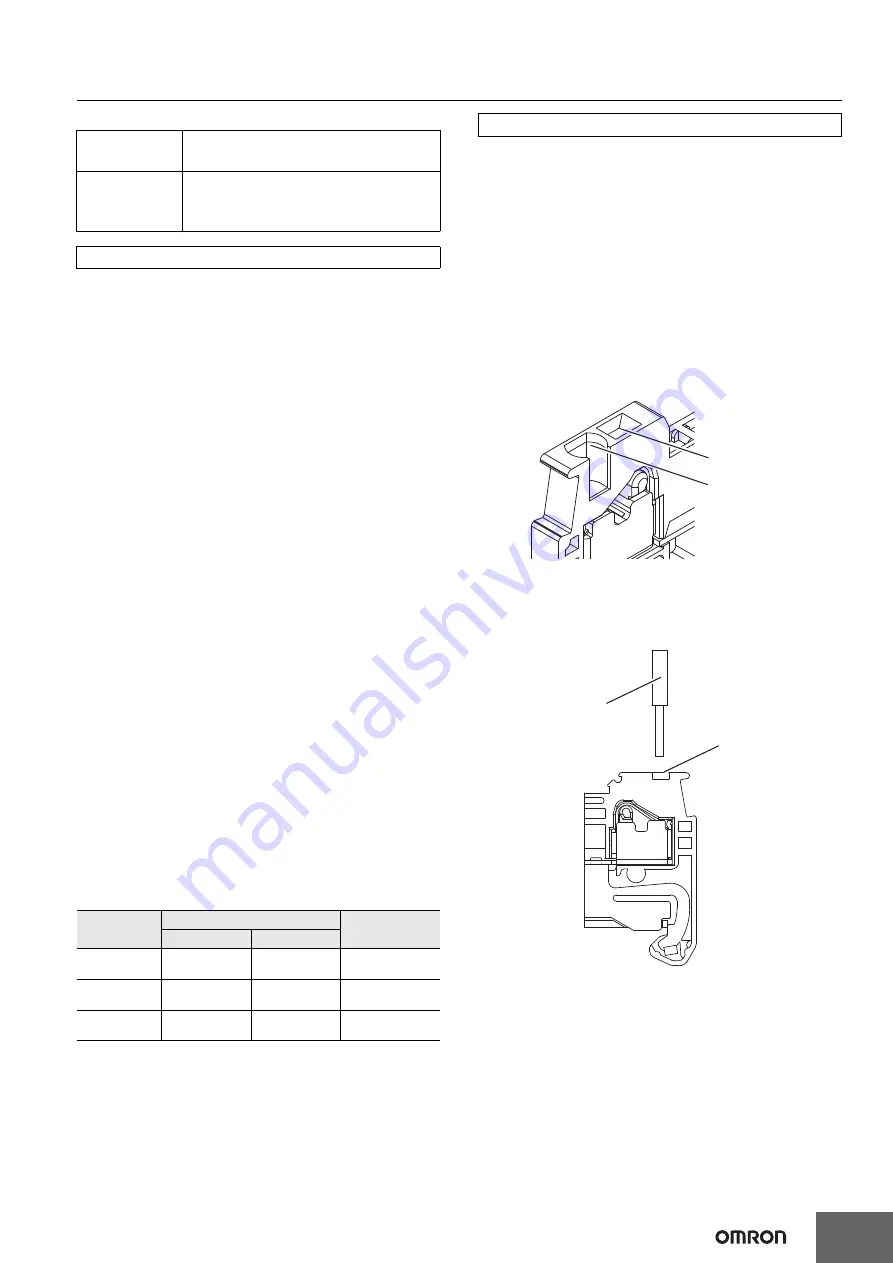

2. Connecting Wires to the Push-In Plus Terminal

Block

Part Names of the Terminal Block

Connecting Wires with Ferrules and Solid Wires

Insert the solid wire or ferrule straight into the terminal block until the

end strikes the terminal block.

If a wire is difficult to connect because it is too thin, use a flat-blade

screwdriver in the same way as when connecting stranded wire.

Precautions

for Safe Use

Supplementary comments on what to do or

avoid doing, to use the product safely.

Precautions

for Correct

Use

Supplementary comments on what to do or

avoid doing, to prevent failure to operate,

malfunction, or undesirable effects on

product performance.

Precautions for Safe Use

Recommended Wire

Stripping length

(Without Ferrules)

Solid

Stranded

XW5T-P1.5-

@

XW5G-P1.5-

@

0.14 to 1.5 mm

2

/

AWG 26 to 14

0.14 to 1.5 mm

2

/

AWG 28 to 16

8 mm

XW5T-P2.5-

@

XW5G-P2.5-

@

0.14 to 4.0 mm

2

/

AWG 26 to 12

0.14 to 2.5 mm

2

/

AWG 26 to 14

10 mm

XW5T-P4.0-

@

XW5G-P4.0-

@

0.25 to 6.0 mm

2

/

AWG 24 to 10

0.25 to 4.0 mm

2

/

AWG 24 to 12

12 mm

Precautions for Correct Use

Release hole

Terminal (Insertion) hole

Ferrule or solid wire

Terminal (Insertion) hole