53

Setup Manual

S

E

CT

IO

N 4

Spe

c

ifi

cati

ons and D

imen

s

ion

s

SECTION 4

Appendix

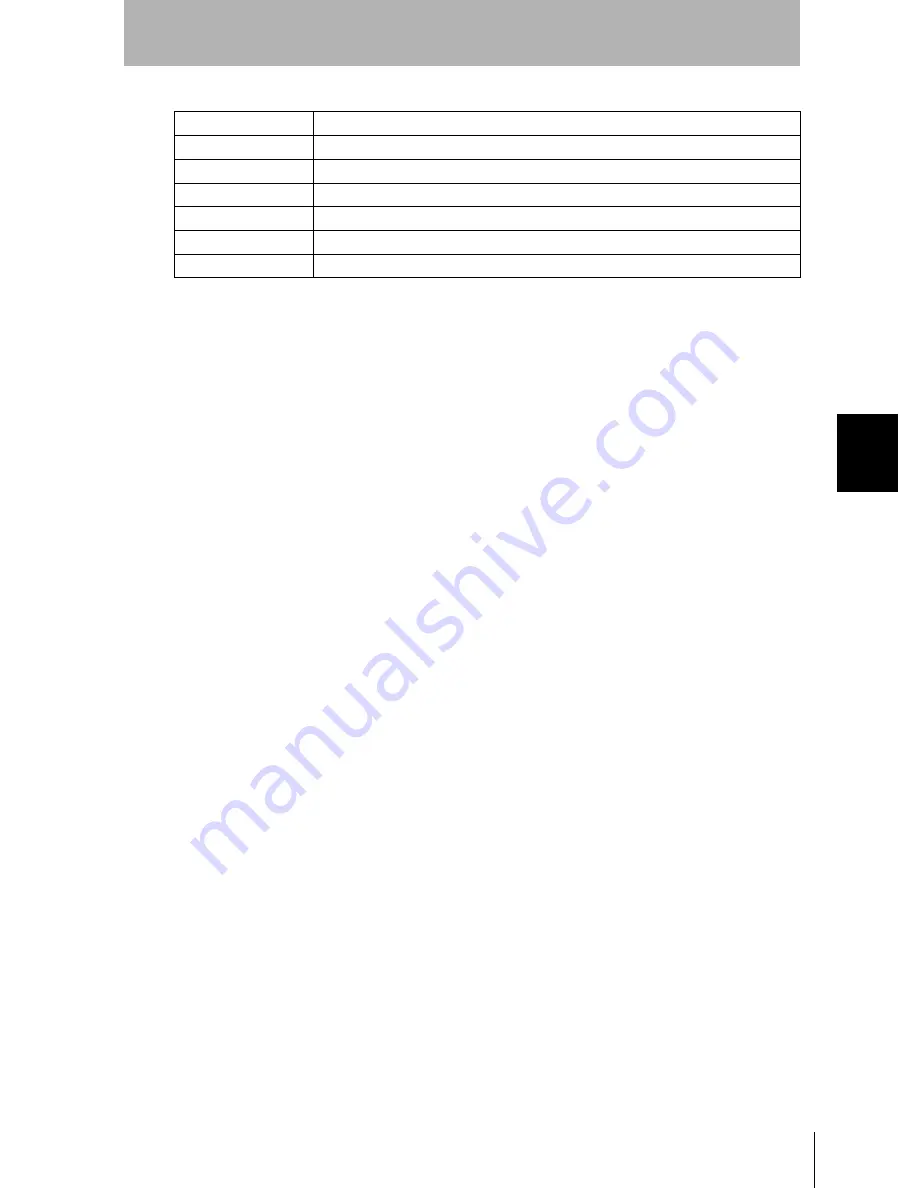

Image pitch

0.348 (H) x 0.348 (V) mm

Contrast

85:1 (typical)

Viewable angle

25

°

up/down and 50

°

left/right (with a contrast ratio > 10)

Luminance

250 cd/m

2

(typical)

Backlight

Cold cathode fluorescent light

Response speed

60 ms max.

Input signal

NTSC composite video (1.0 V/75

Ω

termination)

Performance specifications