Communication Using I/O Signals

112

ZG User’s Manual

Assignments and Functions of I/O Signal Wires

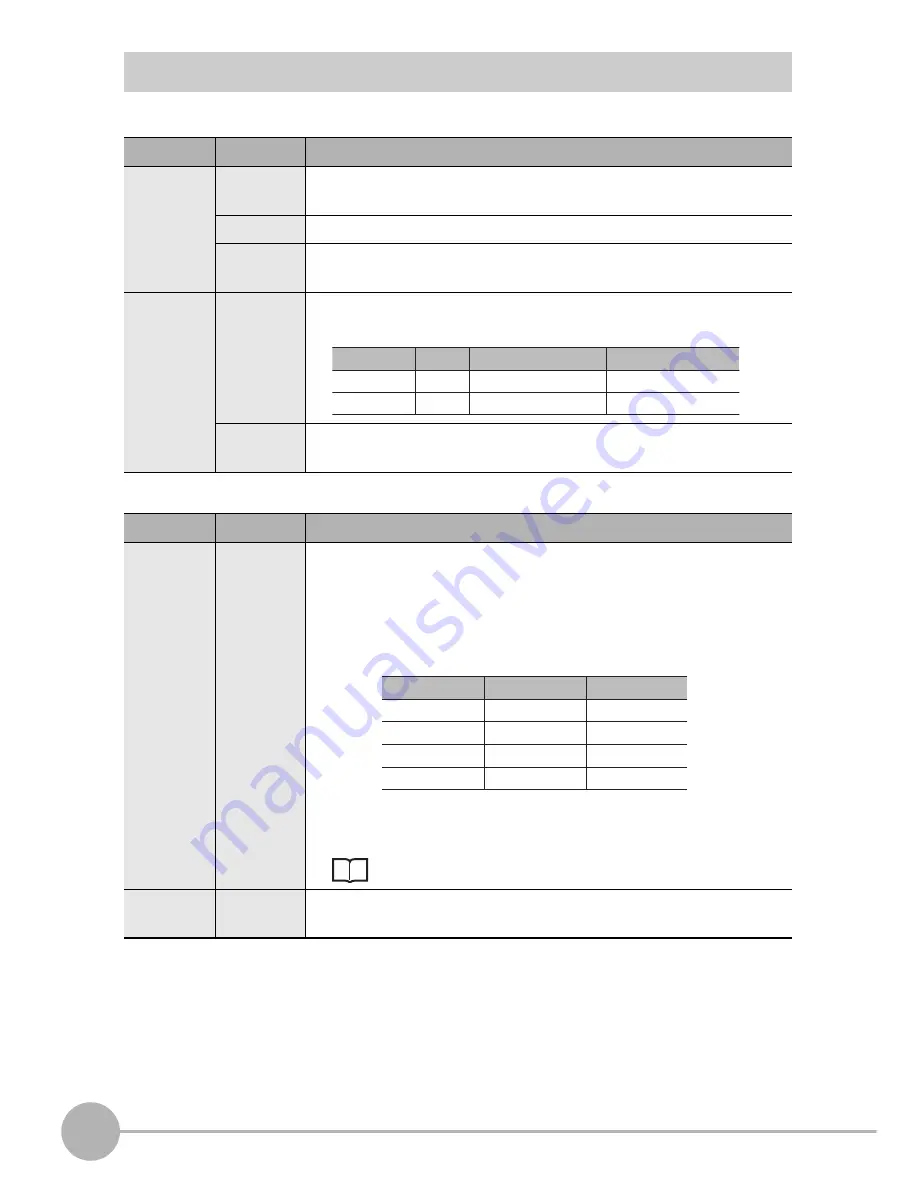

Assignment of output signal wires

Assignment of input signal wires

Function

Signal

Description

Judgment

output

ALL-PASS Turns ON when the judgment result of all tasks is OK (or all tasks

are not registered).

NG

Turns ON when there is even one task whose judgment result is NG.

ERROR

Turns ON when there is even one task for which a measurement

error occurred.

Trigger

auxiliary

ENABLE

Turns ON when trigger input is enabled during trigger measurement.

Turns OFF during bank switching.

GATE

Turns ON when the measurement result is being fixed.

(The startup and output times can also be set.)

Function

Signal

Description

Bank

switching

BANK A/

BANK B

This is used for switching banks. Specify the bank No. in

combinations of A and B.

Bank Nos. that can be switched by input signal wires are banks 1 to

4. If banks 5 to 16 must be switched, switch by using serial

communication commands or by operating the keys on the

Controller.

ENABLE output becomes OFF during bank switching. (when a

trigger is enabled)

Bank switching time p.124

Stop laser

LD-OFF

Stops laser lighting (emission). While LD-OFF is being input, linear

output and judgment output conform to the non-measurement setting.

Regular During trigger measurement

ON

ON

Trigger

Continuous

OFF

-

Ban

k

switching in progress

OFF

OFF

Selected ban

k

BANK A

BANK B

OFF

OFF

ON

ON

Ban

k

1

Ban

k

2

Ban

k

3

Ban

k

4

OFF

ON

OFF

ON

Summary of Contents for ZG -

Page 12: ...10 ZG User s Manual MEMO ...

Page 44: ...Overview of Settings and Measurement 42 ZG User s Manual MEMO ...

Page 60: ...Functions Operations Used during Operation RUN Mode 58 ZG User s Manual MEMO ...

Page 110: ...System Settings 108 ZG User s Manual MEMO ...

Page 156: ...Serial Communication 154 ZG User s Manual MEMO ...

Page 206: ...204 ZG User s Manual MEMO ...

Page 207: ...205 ZG User s Manual 5 APPENDICES MEMO ...

Page 208: ...206 ZG User s Manual MEMO ...