Section6

I/

O

Section6

Timing Charts

6-25

ZS-HL

User’s Manual

●

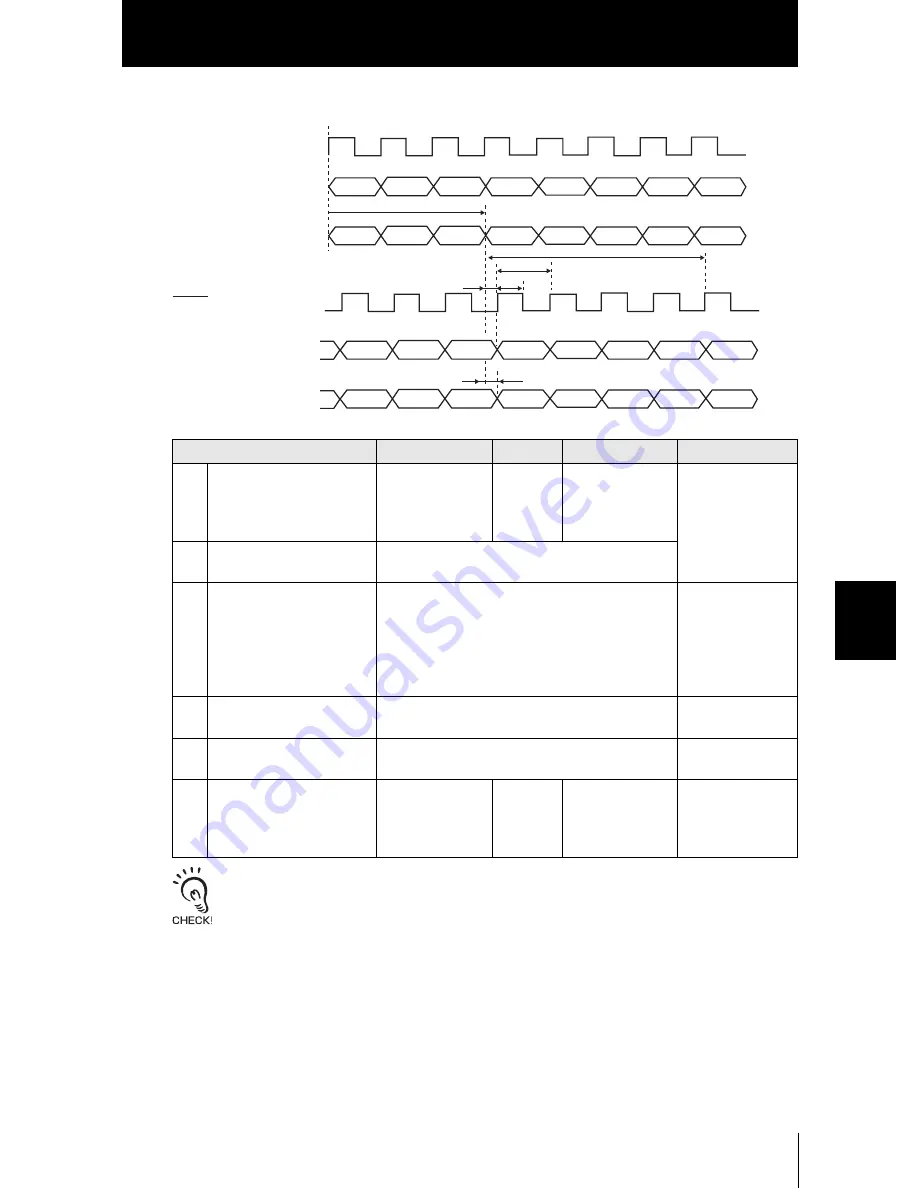

When Measured Value is Output Continuously

To the terminal block, only the result of the TASK for which the measurement is performed is output.

You can judge which TASK number it is by checking the lower 2 bits of the 16-bit output value.

To the linear output, only one selected TASK result is output.

Item

Minimum

Average

Maximum

Remarks

T1

Time during which the mea-

sured value is determined

from the laser beam emis-

sion

-

–

Sampling cycle ×

3

The update cycle

can be set in [I/

OSET]-[TERMI-

NAL BLOCK]-

[CYCLE].

T9

Update cycle of terminal

block output

Sampling cycle × update cycle

T10 OFF time of GATE signal

68 µs

When the mea-

surement is per-

formed

continuously and

the amount of light

is stable

T18 Update cycle of terminal

block output 2

Sampling cycle × update cycle × (number of

TASKs that have been performed)

T21 Response time of GATE

signal

320 µs

T11 Response time of linear

output

–

–

500 µs

It changes

depending on the

way the measured

value fluctuates.

T1

T10

T21

T11

T9

TASK2

TASK3

TASK4

TASK1

TASK2

TASK3

TASK4

TASK1

TASK*

TASK*

TASK*

TASK*

TASK*

TASK*

TASK*

TASK*

T18

ON

OFF

OFF

ON

Laser beam emission

Internal processing

Judgment output

Terminal block output

Linear output

GATE signal

Summary of Contents for ZS--LD10GT

Page 1: ...Smart Sensor 2D CMOS Laser Type Cat No Z236 E1 02A ZS HL Series USER S MANUAL ...

Page 32: ...1 10 Section 1 FEATURES ZS HL User s Manual Section 1 Setting Flow MEMO ...

Page 52: ...2 20 Section2 INSTALLATION CONNECTION ZS HL User s Manual Section2 SmartMonitor ZS MEMO ...

Page 104: ...5 30 Section5 SETTINGS FOR FUNCTIONS ZS HL User s Manual Section5 Clearing the Settings MEMO ...

Page 206: ...9 20 Section9 APPENDIX ZS HL User s Manual Section9 Updating Firmware MEMO ...

Page 210: ...9 24 ZS L User s Manual Section9 Index Section9 APPENDIX MEMO ...