Installation Instructions EC 2-25 Lift

(Subject to technical alterations! - Status 09/2018)

This is a translation. The German original shall prevail.

Page 31 of 50

•

The switching lug must be fitted onto the thread of the brake magnet tappet.

•

The sensor must be installed in the front drill hole with an air clearance of 3,0mm be-

tween the sensor and brake solenoid. The sensors must be adjusted while the brakes are

closed.

Inductive Brake Function Sensor Information

:

Calculated switch clearance: 4,5mm

Standard Function – The electrical circuit is closed when the brake is open

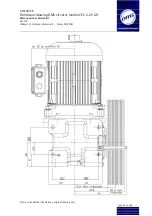

6.7

Adjusting the break lining wear control

Fig. 13

•

The sensor for the brake lining wear is fitted in the external drill hole of the brake lever.

•

A spacing of 11mm / (14mm) is set for new machines in the factory, and should not be

adjusted. The sensor respond, if the brake lining at the front edge of the brake lever has

reached a thickness of 1mm. The machine can still be used. The levers must be replaced.

•

If it is necessary to replace the two brake levers a distance of 11mm / (14mm) must be set

for the new linings.

Information about the inductive brake lining wear sensor

:

Calculated switch clearance: 4,5mm

Standard Function – electric circuit by worn brake lining closed

11mm / 14mm

Sensor M12 x 1 CLOSER

Summary of Contents for Hypodrive EC 2-25 Lift

Page 2: ......