SKU 94593

For technical questions, please call 1-800-444-3353

Page 5

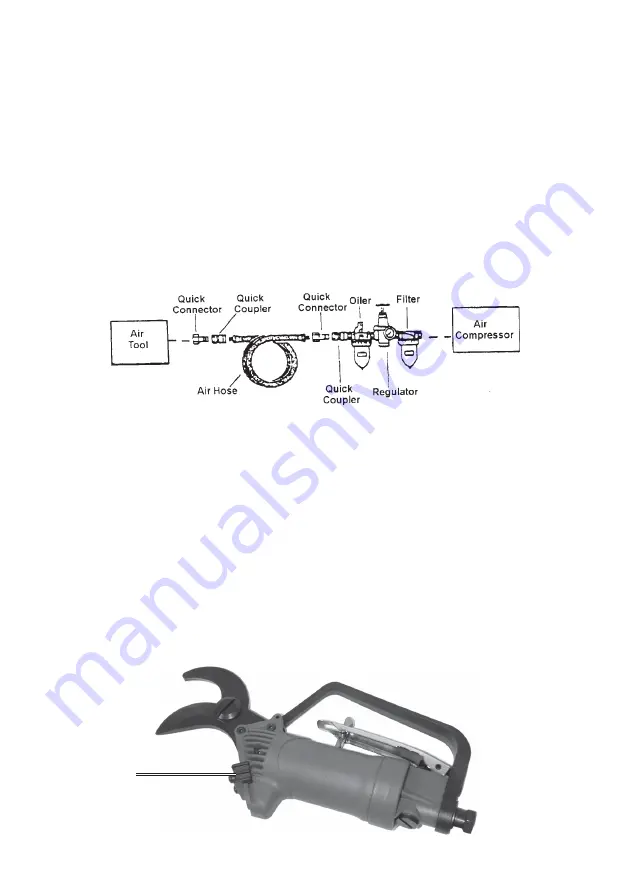

Oiler and Filter Connection

Dirt, water, and the lack of pneumatic tool oil are major causes for tool wear. Install

an optional oiler-filter, as illustrated below for better performance.

1.

Connect the air tool, air hoses, filter, and oiler to the Compressor Air Outlet

as illustrated below.

The filter and oiler (not supplied) are recommended but not mandatory for

operation. Also, for ease of air supply transport, a portable, rechargeable air

supply would make it easier to maneuver the garden for trimming.

If the filter and oiler are not used, connect the air hose directly to the 1/4 inch,

18 NPT connector located at the Air Inlet (12) fitting. Also, a few drops of

pneumatic tool oil must be added through the Air Inlet (12) before each use.

Note: Use pipe thread seal or Teflon tape on all threaded connections.

Operation

1.

Place the air supply, sufficient length of air hose, and Pneumatic Shears near

the tree or shrubs to be trimmed.

2.

Turn the air pressure on at the air supply tank or compressor.

3.

Brace yourself on the ground or ladder, then grasp the Pneumatic Shears by

the handle.

4.

Place the open blades over the branch to be cut.

5.

Pull the Blade Safety Latch (38) down to unlock the blades.

Blade Safety

Latch (38)