VI. Assembly Instructions

(Cont.)

O.A.S. 2002

c

5 - 7.5 HP Direct Drive Owner’s Manual

8

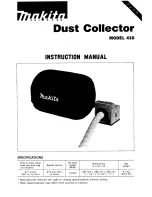

5. Attach flex hose to bottom of collector and to lid of

dust bin. Securely fasten hose clamps. There must be

an air tight seal between the collector and dust bin.

6. Make sure the dust bin lid sits securely and the rubber

gasket on the bin lid is in place on the barrel. Maintain

an air tight seal between cyclone and dust bin to prevent

motor from overloading.

IMPORTANT:

Do not operate the collector until the dust bin is in place and

the connector is air tight or motor damage could result!

Stay clear of fan exhaust while collector is operating.

Collector

Hose Clamp

Hose Clamp

Flex Hose

Dust Bin

4.

7. Attach the ductwork from the woodworking machines to the inlet of the collector.

8. On external filter models, attach the Plenum Assembly or connect to your own plenum box.

9. Attach feet of Angle Iron Stand to floor.

Note: Assembly with Tube Filters - Note plenum height requirements of Tube Filters - 6’ tubes - 8’ plenum / 8’ tubes -

10’ plenum / 10’ tubes - 12’ plenum. Adjust system height accordingly.

VII. Fan / Blower Maintenance

A high pressure blower requires a certain amount of resistance which will prevent motor

over amperage.

Make sure power source matches wire voltage configurations.

Check set screw and key in fan wheel, make sure fan wheel is secure. Fan blower should

not vibrate.

1. Electrical -

Failure to follow instructions and safe electrical procedures could result in serious injury or death.

Disconnect all power and discharge all capacitors before servicing. Install and ground per local and national

codes. Consult a licensed electrician with questions or if repairs are required.

Electrical Connections -

A.) All wiring, fusing, and grounding must comply with National Electrical Codes and local codes.

B.) To determine proper rotation and voltage connections, refer to the Wire Diagram of this manual.

C.) Use the proper size of line current protection and motor controls as required by the National Electrical Code

and local codes. Recommended use is 125% of full load amps as shown on the nameplate for motors with

40 degrees Celsius ambient and a service factor over 1.0. Recommended use is 115% of full load amps as

shown on the nameplate for all other motors. Do not use protection with larger capacities than recommended.

Three phase motors must have all three phases protected.

2. Cleanliness -

Keep both the interior and exterior of the motor free from dirt, water, oil, and grease.

3. Safety -

Motors should be installed, protected and fused in accordance with latest issue of National Electrical

Code, NEMA Standard Publication No. MG 2 and local codes. Rotating parts such as pulleys, coupling, external

fans, and unusual shaft extensions should be permanently guarded. Keep hands and clothing away from

moving parts. Electrical repairs should be made by trained, qualified personnel only.

4. Service - Notice -

If lubrication instructions are shown on the motor nameplate, they will supercede this

general instruction.

Warning: Rotating Fan Blades. Keep Objects Clear of Inlet and Outlet.