8. Hardware Specification

8.1. Technical Sheets

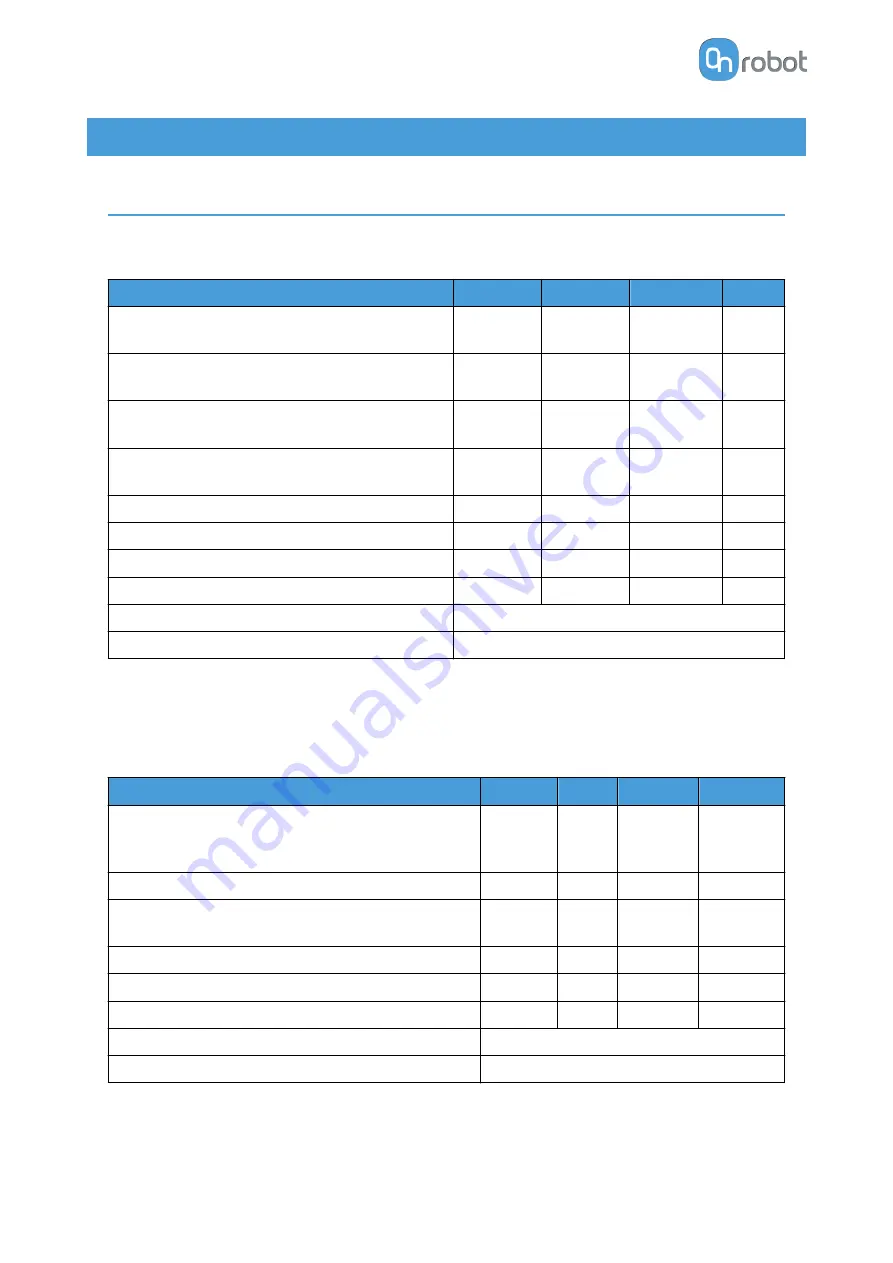

8.1.1. 2FGP20

Finger Grip Properties

Minimum Typical

Maximum

Unit

Payload

-

-

-

-

20

44.1

[kg]

[lb]

Total stroke

-

-

260

10.24

[mm]

[inch]

Grip width range *

170

6.69

-

430

16.93

[mm]

[inch]

Gripping repeatability

-

-

+/- 0.5

+/- 0.0197

-

-

[mm]

[inch]

Gripping force **

80

-

400

[N]

Gripping force tolerance

-

-

+/- 30

[N]

Gripping speed ***

16

-

180

[mm/s]

Gripping time (including brake activation)

-

600

-

[ms]

Hold workpiece if power loss?

Yes

Motor

Integrated, electric BLDC

* When pads are mounted, the minimum value is 158 mm and the maximum value is 418 mm.

** See

*** At 6 mm stroke and 150 N. The typical value is 900 ms at 20 mm and 200 N.

Vacuum grip properties

Minimum Typical Maximum Unit

Vacuum

5

- 0.05

1.5

-

-

-

60

- 0.607

17.95

[%Vacuum]

[Bar]

[inHg]

Air flow

0

12

[L/min]

Payload (with delivered attachments)

-

-

2.5

5.51

[kg]

[lb]

Vacuum cups

1

4

[pcs]

Gripping time (measured with vacuum target 40 %)

0.25

[s]

Release time

0.4

[s]

Vacuum pump

Integrated, electric BLDC

Dust filters

Integrated 50 µm, field replaceable

HARDWARE SPECIFICATION

58

Summary of Contents for 2FGP20

Page 1: ...USER MANUAL FOR UR ROBOTS v1 13 0 Original Instructions...

Page 62: ...Illustration Pad position Maximum force N 2 200 3 100 4 400 HARDWARE SPECIFICATION 62...

Page 71: ...8 2 3 Tools 8 2 3 1 2FGP20 All dimensions are in mm and inches HARDWARE SPECIFICATION 71...

Page 79: ...12 Certifications CERTIFICATIONS 79...

Page 80: ...12 1 EMC 12 2 2FGP20 Environment CERTIFICATIONS 80...

Page 81: ...12 3 Declaration of Incorporation 12 3 1 2FGP20 CERTIFICATIONS 81...