4.2.2. Quick Changer Mounting

4.2.2.1. Quick Changer - Robot Side

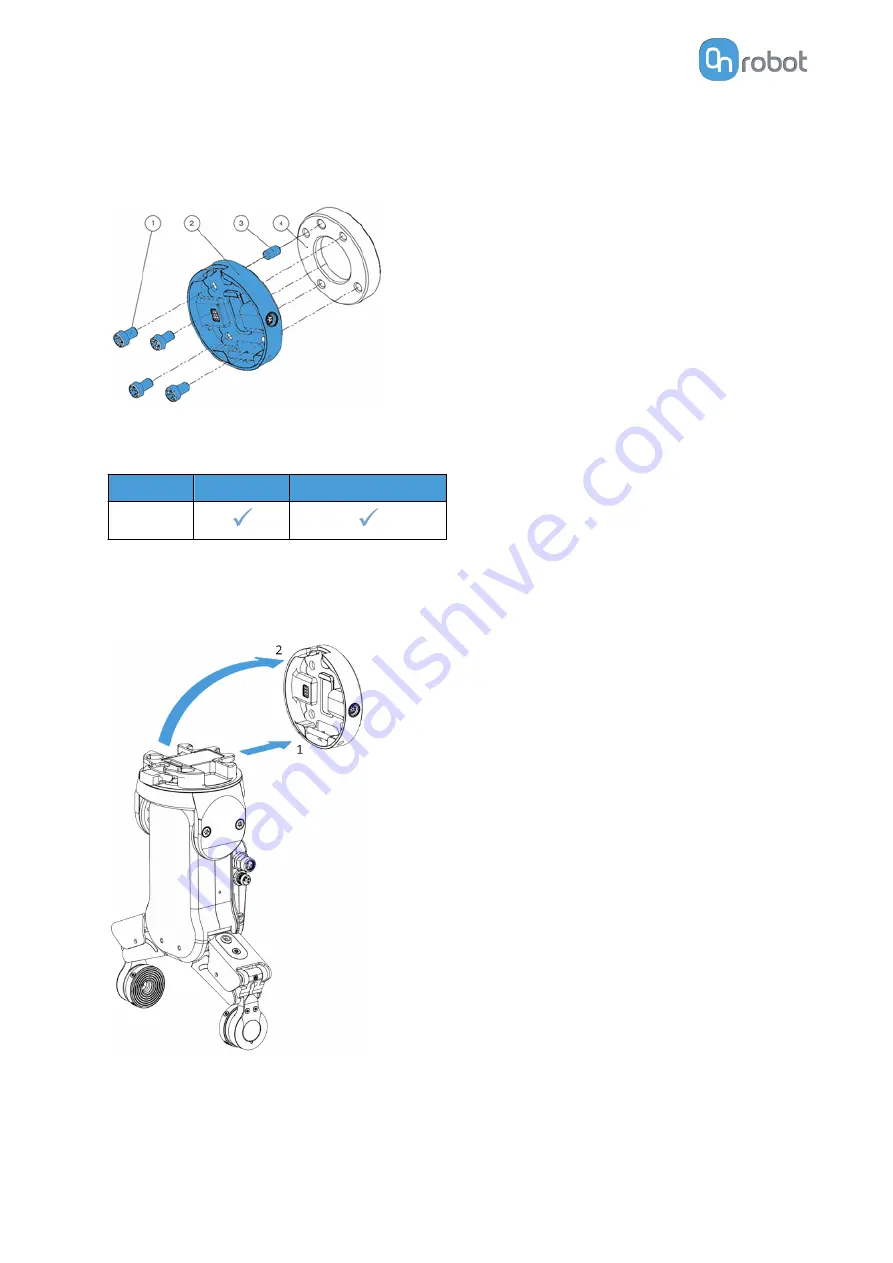

Quick Changer - Robot Side

1. M6x8mm (ISO14580 8.8)

2. Quick Changer (ISO 9409-1-50-4-

M6)

3. Dowel pin Ø6x10 (ISO2338 h8)

4. Adapter/ Robot tool flange (ISO

9409-1-50-4-M6)

Use 10 Nm tightening torque.

4.2.2.2. RG2-FT

Tool

QC-R v2

QC-R v2-4.5 A

RG2-FT

4.2.3. Tools

4.2.3.1. RG2-FT

Step 1:

Move the tool close to the Quick Changer as

illustrated.

The hook mechanism (rod and hook tongue)

will keep the lower part locked once mounted.

Step 2:

Flip the tool until it is fully mated, and you hear

a clicking sound.

To unmount the tool, press the aluminum

button on the Quick Changer and repeat the

steps in the reverse order.

HW INSTALLATION

12

Summary of Contents for RG2-FT

Page 1: ...USER MANUAL FOR UR ROBOTS v1 4 1 Original Instructions ...

Page 66: ...Proximity Sensor Typical Accuracy HARDWARE SPECIFICATION 66 ...

Page 68: ...Dimensions of the Gripper s finger in millimeters HARDWARE SPECIFICATION 68 ...

Page 74: ...8 2 4 Tools 8 2 4 1 RG2 FT All dimensions are in mm and inches HARDWARE SPECIFICATION 74 ...

Page 82: ...12 Certifications CERTIFICATIONS 82 ...

Page 83: ...12 1 EMC CERTIFICATIONS 83 ...

Page 84: ...12 2 Declaration of Incorporation 12 2 1 RG2 FT CERTIFICATIONS 84 ...