HOBO Light On/Off Data Logger (UX90-002x) Manual

1-800-LOGGERS 4

www.onsetcomp.com

Time

Between

Events

Approximate

Total Data

Points

Approximate

Logging Duration

(1 Year Battery Life)

Logger Part

Number

4.26 to

68.25

minutes

50,790

150.49 days to 6.6 years

UX90-002

208,077

1.69 years to 2.7

decades

UX90-002M

68.26

minutes

to 18.2

hours

42,325

5.5 years to 8.8 decades

UX90-002

173,397

2.25 to 36.03 decades

UX90-002M

Notes:

•

Typical battery life is 1 year when state changes are at 1

minute or greater intervals.

•

The logger can record battery voltage data in an additional

channel. This is disabled by default. Recording battery

voltage reduces storage capacity and is generally not used

except for troubleshooting.

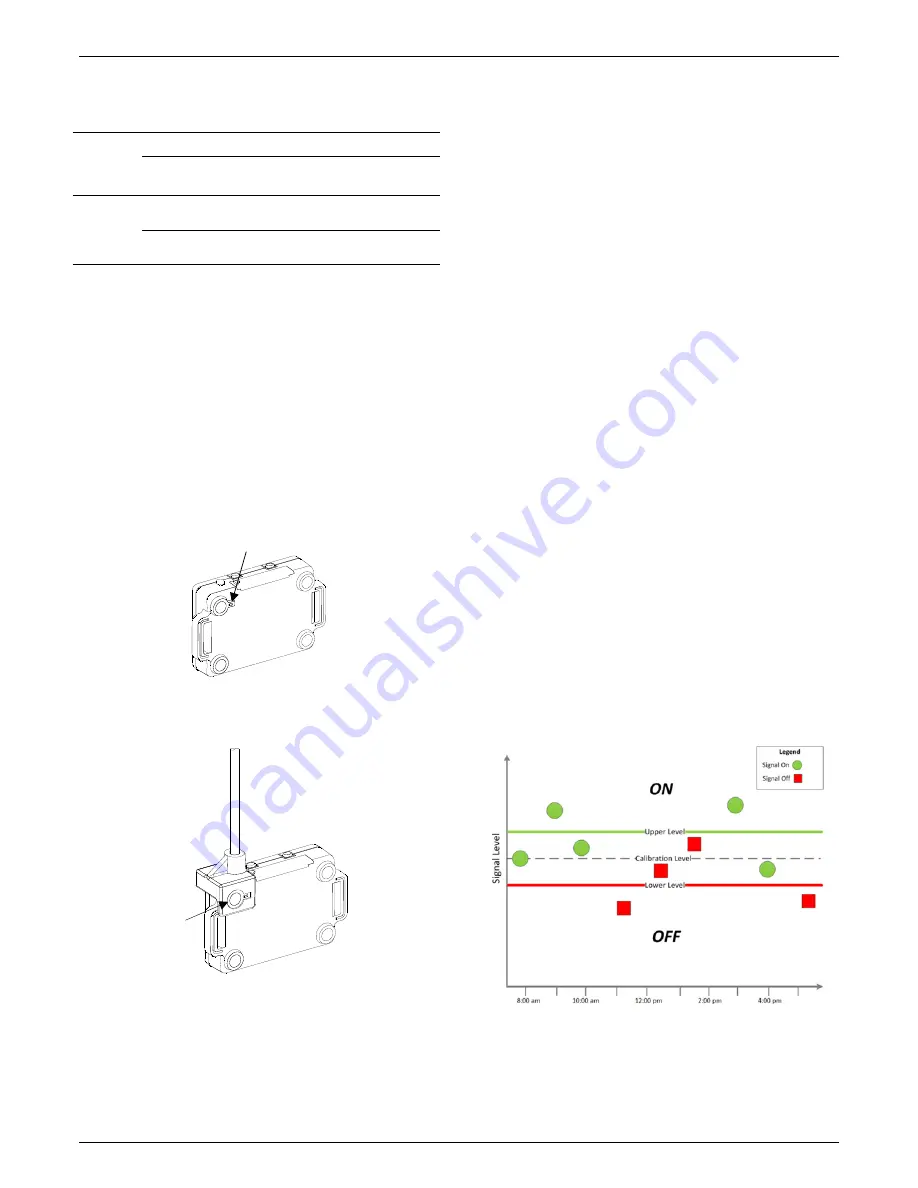

Using the Logger with the Light Pipe

An optional fiber optic attachment or light pipe (UX90-LIGHT-

PIPE-1) is available for this logger. This attachment connects to

the back of the logger. To install it:

1.

Locate the notch in the upper left corner next to the

mounting magnet.

2.

Insert the black base of the attachment into the notch so

that the base clips onto the corner of the logger as shown

below.

Follow these guidelines when using a light pipe:

•

Make sure the end of the light pipe is as close to the light

source as possible.

•

Avoid 90-degree bends. The light pipe is flexible and can

be bent to gain access to hard-to-reach areas, but should

not have any sharp, 90-degree bends.

•

Maximize the signal strength on the logger LCD screen

by adjusting the light pipe while looking at the signal

bars (see

Calibrating the Light Sensor

for more details

on signal strength).

•

Be sure to secure the light pipe after the signal has been

optimized.

•

Do not support the logger by the light pipe.

•

Be sure that the pipe is seated all the way into the bracket

before deployment.

Calibrating the Light Sensor

Each time you place the logger in a new lighted environment,

you should calibrate it to the light level that you will be

monitoring. This ensures the logger is accurately determining

when the light changes between ON and OFF states. There are

two calibration methods available: auto-calibration (button

calibration) or preset calibration via HOBOware.

Auto-calibration is used to calibrate the ON and OFF threshold

of the logger to achieve reliable readings in an environment

where ambient conditions are unknown prior to deployment or

where logger light levels are variable.

In the auto-calibration

process, the light is measured via a built-in analog-to-digital

converter and the resulting value is used to generate a

calibration threshold.

Note:

Auto-calibration (button

calibration) must be done at the location where the logger will

be deployed.

Preset values are used when light levels are known in advance

and deployment speed is critical.

The logger has a built-in hysteresis level of approximately

±12.5% to prevent the sensor from toggling between ON and

OFF when the light level is near the calibration threshold. This

plot shows how the logger handles hysteresis. The logger

interprets the signal, or light, as ON until it drops below the

lower level of the calibration threshold. Once it switches to off,

the signal will not switch back to ON until it bypasses the upper

limit of the calibration level.

When auto-calibrating from the logger (button calibrating):

1.

After launching, deploy the logger near the light source to

be monitored and turn the light source on.

Notch on back of logger

Base of attachment

inserted into notch

Distributed by MicroDAQ.com, Ltd. www.MicroDAQ.com (603) 746-5524