HOBO Light On/Off Data Logger (UX90-002x) Manual

1-800-LOGGERS 5

www.onsetcomp.com

2.

Press the Calibrate button for 1 second. The LCD screen will

display the signal strength of the light. The signal strength

should ideally be at least 3 bars. Orient the logger as

necessary to increase the signal strength.

3.

Press the Calibrate button for 3 seconds while “HOLD”

appears on the LCD screen. Move your hand away from the

logger to prevent shadowing. The logger will count down to

the auto-calibration and then display either “PASS” or

“FAIL” after calibration is complete.

4.

If the auto-calibration fails, point the sensor directly at the

light source and then repeat these steps.

If you cannot manipulate the light source, you can set the

calibration level in HOBOware. To do this:

1.

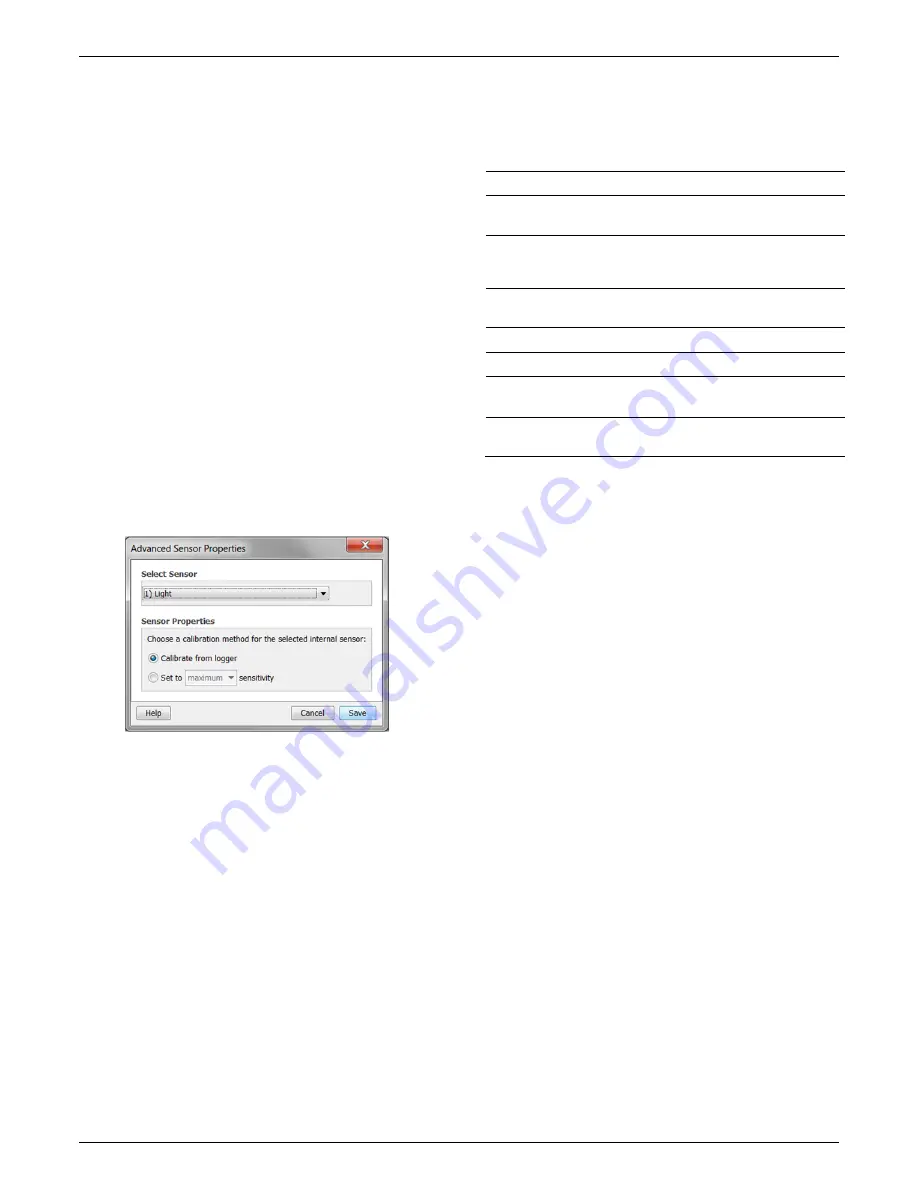

Click the Advanced button in the Launch Logger window.

2.

The lower the light level, the higher the sensitivity needs to

be to record changes between ON and OFF conditions.

Therefore:

•

For rooms with low light levels, such as residential

environments, select “Set to maximum sensitivity,” which

has a threshold set to approximately 100 lux.

•

For rooms with high light levels, such as retail

environments, select “Set to minimum sensitivity,” which

has a threshold set to approximately 500 lux.

Note:

The sensor is sensitive to lights that emit high

amounts of infrared radiation like incandescent and

halogen bulbs. It is best to use auto-calibration when

possible when monitoring on/off conditions for lights with

high infrared radiation.

3.

Click Save. Note that the selections will not take effect in

the logger until you launch it.

Reading Out the Logger

There are two options for reading out the logger: connect it to

the computer with a USB cable and read out it with HOBOware,

or connect it to a HOBO U-Shuttle (U-DT-1, firmware version

1.15m030 or higher) and then offload the data files from the

U-Shuttle to HOBOware. Refer to the HOBOware Help for

details.

Recording Internal Logger Events

The logger records the following internal events to help track

logger operation and status:

Internal Event Name

Definition

Host Connected

The logger was connected to the computer.

Started

The Start/Stop button was pressed to begin

logging.

Stopped

The logger received a command to stop

recording data (from HOBOware or by

pushing the Start/Stop button).

Internal Calibration

The logger was calibrated via auto-

calibration (button calibration).

Host Calibration

The logger was calibrated via HOBOware.

Calibration Failure

Calibrating the logger has failed.

Button Up/Button

Down

The Start/Stop button was pressed for

1

second.

Safe Shutdown

The battery level dropped below 2.5 V; the

logger performs a safe shutdown.

Mounting the Logger

There are several ways to mount the logger using the materials

included:

•

Use the four built-in magnets on the back of the logger to

mount it to a magnetic surface.

•

Attach the Command strip to the back of the logger to

mount it a wall or other flat surface.

•

Use the double-sided tape to affix the logger to a surface.

•

Insert the hook-and-loop strap through the mounting

loops on both sides of the logger to mount it to a curved

surface, such as a pipe or tubing.

Protecting the Logger

The logger is designed for indoor use and can be permanently

damaged by corrosion if it gets wet. Protect it from

condensation. If the message FAIL CLK appears on the LCD

screen, there was a failure with the internal logger clock

possibly due to condensation. Remove the battery immediately

and dry the circuit board.

Note:

Static electricity may cause the logger to stop logging.

The logger has been tested to 8

KV, but avoid electrostatic

discharge by grounding yourself to protect the logger. For more

information, search for “static discharge” in the FAQ section on

onsetcomp.com.

Battery Information

The logger is installed with a 3V CR2032 battery (HRB-TEMP).

Expected battery life varies based on the ambient temperature

where the logger is deployed, the logging interval, the rate of

state changes, the frequency of offloading to the computer,

and battery performance. A new battery typically lasts 1 year

with a logging interval greater than 1 minute. Deployments in

extremely cold or hot temperatures or a logging interval faster

than 1 minute may reduce battery life. Estimates are not

guaranteed due to uncertainties in initial battery conditions and

operating environment.

Distributed by MicroDAQ.com, Ltd. www.MicroDAQ.com (603) 746-5524