DX26/DX32 OPERATOR MANUAL

12

Rev 4 –11/4/2021

MACHINE OPERATION

Machine Operation Set-up & Water Flow Adjustment

Conventional Scrubbing/Cleaning:

Fill the cleaning liquid tank with desired cleaning solution.

Make sure the recovery tank is empty before you start the

operation.

Power machine on by turning the key switch (1) to the ON

position. Check that the battery is well charged on LED

indicator (2), ideally start with a full battery charge. Toggle the

Brush Motor switch (3) to the down position. Lower the

squeegee assembly and turn the vacuum motor on by pulling

lever (4). Manually control the water valve (5) to adjust the

volume of the cleaning liquid (water and detergent) flowing to

the ground.

The brush cleans the floor with the solution, mixing detergent

and water. While the machine advances, pick-up the

wastewater on the floor with the squeegee into the waste

water tank.

Information on Brush and Scouring Pad

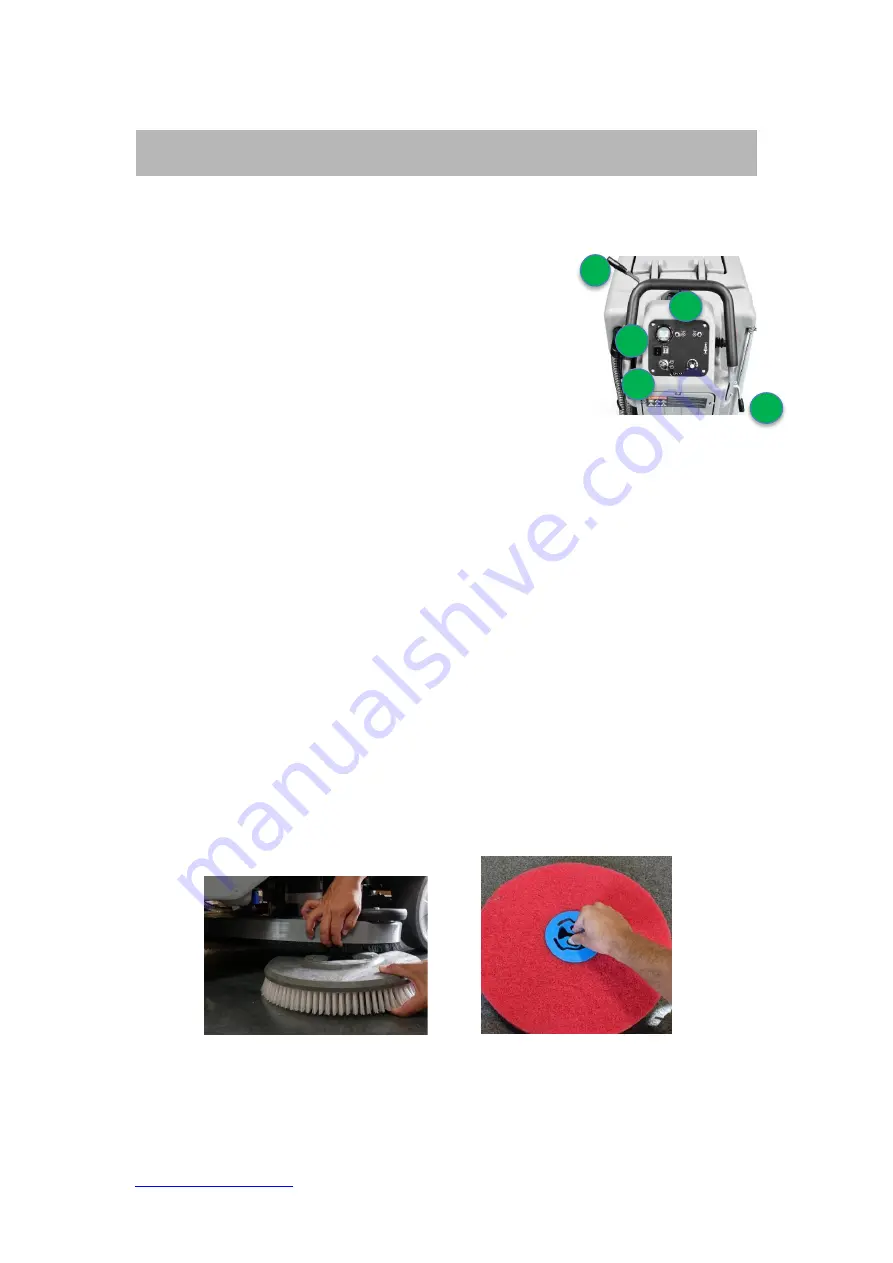

To ensure the optimum efficiency, please use the correct type of brush for cleaning.

The brush and pad suggested for use are as follows:

●

Soft nylon brush (white)

- It is

suggested to clean the coated

floor without damaging the

floor. Clean without scratches.

●

Crash pad (red)

- It is used for

scrubbing slight dirt without

damaging the floor.

●

Polishing pad (white)

- It is

used for maintaining a highly

smooth or polished floor.

●

Gravity folding pad (black)

- It is

used for powerfully removing the

heavy coating or base or super-

powerful scrubbing.

5

1

3

4

2