C-Beam Machine

Wiring & Commissioning

28

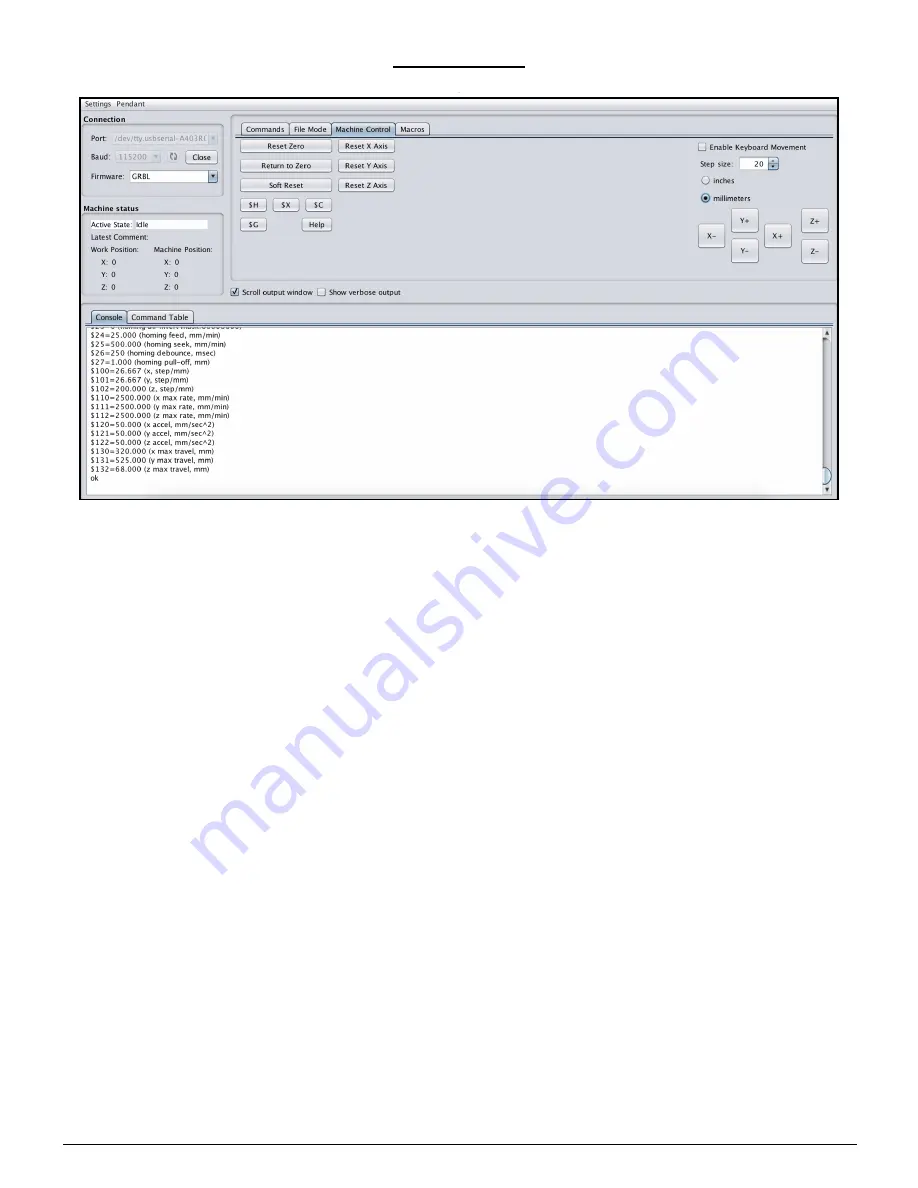

4.3 Testing

A.

To begin testing, disconnect from the CNC-xPro, and move the machine by hand so

that it is in the middle of it’s max travel on all axes.

B.

Switch on the 24V-360W-Power-Supply, and the 2 x 30mm-24V-DC-Fan’s should acti-

vate. If they do not activate, check the wiring in Step 3.0.4.

C.

Reconnect to the CNC-xPro in UGS. Next to each driver on the CNC-xPro, there is a

current control pot, and these can be adjusted using the Ceramic-Screwdriver. Rotate

clockwise to increase the current, and anti-clockwise to decrease. The default posi-

tions should work fine, but they can be adjusted to increase/decrease motor torque or

quiet motor motion. If in Step D below the motors don’t move, first check the wiring in

Step 4.1.3. If that isn’t the issue, then slightly increase the motor current in 1/8th

turns.

D.

Looking from the front of the machine, the correct axes machine motion is: X-Axis

positive to the right, Y-Axis positive going away, Z-Axis positive going up. To test this

in UGS, click on the ‘Machine Control’ tab on the top bar. On the right hand side there

are jog controls. Set the ‘Step size’ to 20 and select ‘millimeters’. Press the ‘X+’ but-

ton to jog the machine in the positive X direction, and the carriage should move to the

right. Press ‘Y+’ and the gantry should move away. Press ‘Z+’ the Z-Axis should go

up.

E.

If in Step C any of the axes have moved in the opposite directions than should be

expected, turn off machine and disconnect from the CNC-xPro. To correct this issue,

locate the motor wire for the axis that is incorrect and flip the wire colour order on the

CNC-xPro. Repeat Steps B, C & D to retest the machine.

F.

Once the motor directions are correct, use the jog controls in UGS to check that the

machine can move through the whole distance of its travels on all axes. If this is

unsuccessful, first check that the ACME-Lead-Screw are attached correctly, aligned,

and not binding. If the assembly is correct, it may be that the drivers on the CNC-xPro

are overheating, so try decreasing the current in 1/8th turns.

Summary of Contents for C-Beam Machine

Page 1: ...C Beam Machine Electrical Assembly Instructions...

Page 2: ......

Page 4: ...C Beam Machine Getting Started 2 1 0 Getting Started...

Page 7: ...C Beam Machine Power Supply Assembly 5 2 0 Power Supply Assembly...

Page 12: ...C Beam Machine Power Supply Assembly 10 2 3 Connecting PSU Cover 2 3 1 Connecting Wires...

Page 17: ...C Beam Machine CNC xPro Assembly 15 3 0 CNC xPro Assembly...

Page 22: ...C Beam Machine CNC xPro Assembly 20 3 0 5 Mounting the CNC xPro Assembly...

Page 24: ...C Beam Machine Wiring Commissioning 22 4 0 Wiring Commissioning...

Page 33: ...C Beam Machine Appendix 31 5 0 Appendix...

Page 38: ...C Beam Machine Appendix 36 Misc 1 x Ceramic Screw Driver 1 x USB Cable...