Summary of Contents for 102.056

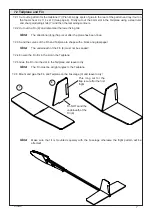

Page 14: ...14 E102056 1...

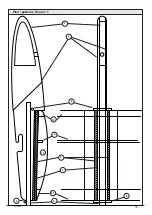

Page 15: ...15 E102056 1 Plan patterns Scale 1 1 1 2 3 11 9 12 5 4 10 6 6 6...

Page 16: ...16 E102056 1...

Page 18: ...18 E102056 1...

Page 20: ...20 E102056 1...

Page 22: ...22 E102056 1...

Page 24: ...24 E102056 1...