2

E106061#1

5.Instructions

5.1 Making the frame and bearing block

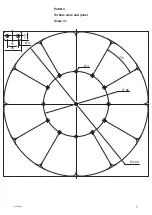

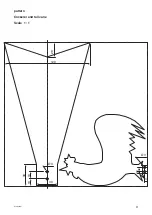

5.2 Making the turbine, cockerel, tail and mechanism

5.3 Mounting the single parts

5

.4 Function control

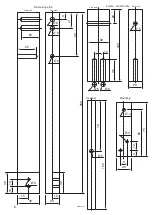

5.1 Making the frame and bearing block

5.1.1 Mark out & drill the blind holes 6 & 5mm diameter as in the drawing (See page 6 ) each 25mm deep in the

pine strip 20x 30x 250mm. At the other end saw a 30mm deep slot for the tail vane.

Finally drill 2 holes 3mm dia as shown in the drawing (See page 6). Sand to finish.

5.1.2 Mark out & drill the 6mm diameter blind hole ( See page 6) in the pine strip 20 x 30 x 100mm. At the other

end drill the 5mm diameter hole for the bearing- sand to finish.

.

5.1.3 Join the two together with the 6dia x 50mm dowel.

Use a cramp to press them together.

5.1.4 Saw from the brass tube 5dia x 245 a 55mm and a 4mm long piece. File the ends clean

Finally place the 45mm long piece as bearing in the long pine strip. Then the 55mm long piece as a bearing

in the shorter piece so that ca 15mm protrudes to the front.

( See photo)

25

25

9

21

60

250

30

30

Ø 3

10 10

30

15

10

Ø 5

Ø 6

Ø 6

20

30

20

100

Ø 6

Ø 6

Ø 5

12

30

20

ca. 15 mm

ca. 10 mm