3

E106061#1

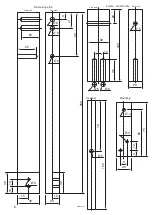

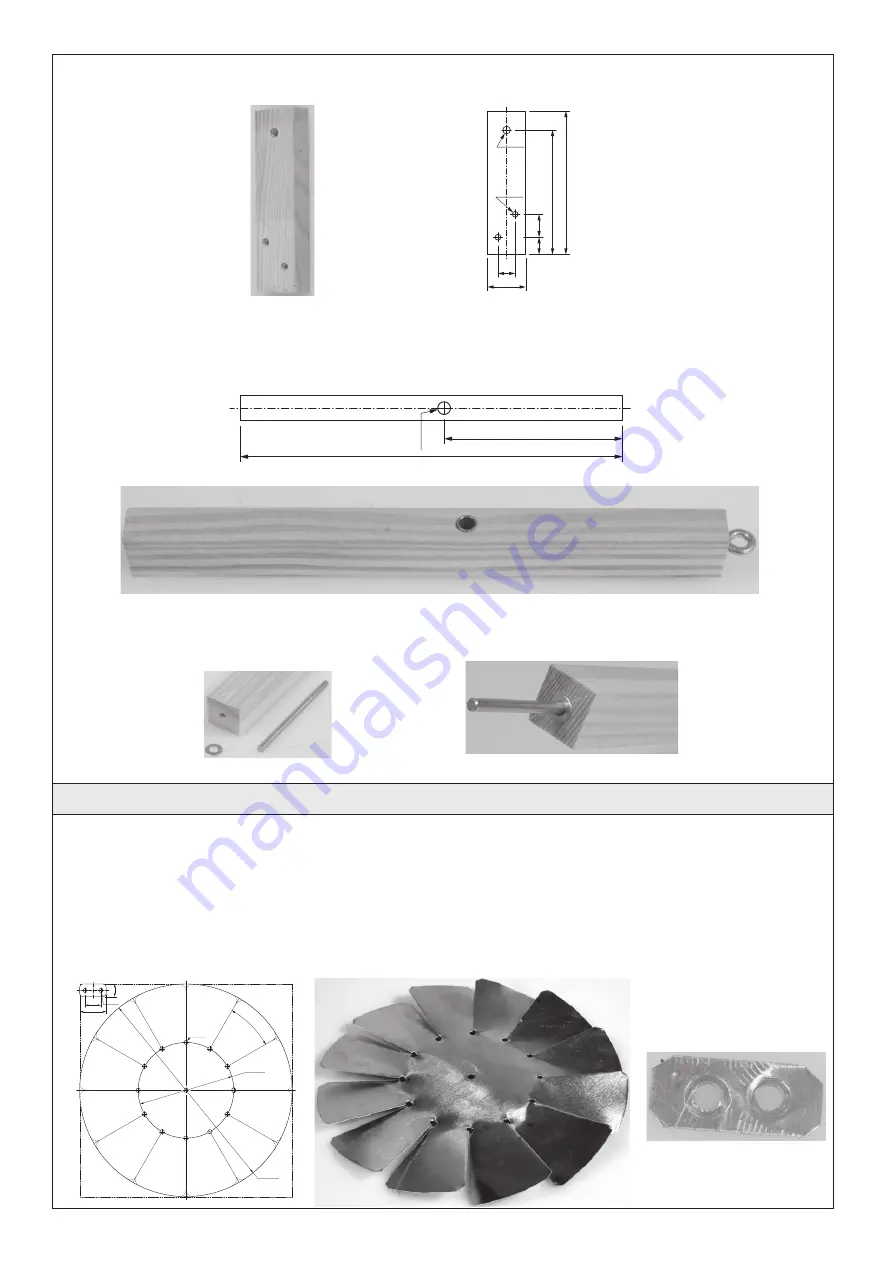

5.1.5 Saw the wood strip 10 x 20 x 150 in half. Then mark out and drill the holes 3dia & 4mm as shown ( See page 6)

5.1.6 Mark out and drill the 5mm hole in the side of the pine strip 10 x 15 x 150mm

Saw 17mm from the remaining brass tube. Remove burr ( File ) from the ends of the tube . Now inset the

tube in the 5mm hole. Insert a ring screw in the end nearest the hole. (See photo )

5.1.7 Drill the bearing block 20 x 20 x 350mm at one end, 4mm dia x 20mm deep

Insert the 4dia x 68mm brass rod in the hole and then add a washer ( So that the turbine will turn easier )

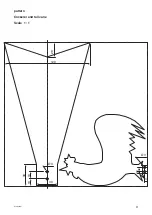

5.2 Making the Turbine, Cockerel, Tail and mechanism

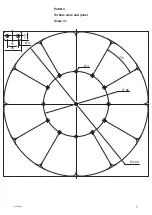

5.21 Trace the drawings ( See page 7) for the turbine & joiner on to the aluminium sheet.

Centre punch all the holes and drill them 4mm dia around and in the middle of the turbine fan. Cut out the

shape with metal shears. Cut out the vanes and round off the corners

- Remove any sharp burr ! Twist the vanes at angle 25-30 degrees

Note:

Be careful of any sharp metal edges !!

Cut out the joiner and file smooth

65

75

9

12

20

Ø 3

Ø 4

9

ca.

70

150

Ø

5

Ø 4

25

12

15

Ø 90

Ø 200

30°

Ø 4