5

E106061#1

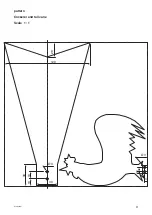

5.3.2 Fix the cockerel with two screws 2,9 x 9,5mm

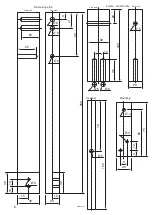

5.3.3 Secure the two bearing blocks on either side of the seesaw mechanism

About 120mm in. Use 3 x 20m screws

Note

Make sure the bearing holes are in line with each other!

Arrange the bearing blocks so that the screws are not in line with each other

5.3.4 Use the 4 x 50mm to hold the see-saw mechanism between the bearing blocks

Lock with 2 nuts so that it will move easily up and down

5.3.5 Open the free end of the connecting rod and connect it to the screw eye in the end of the seesaw.

5.3.6 Paint the finished model to your own taste. The wood parts can be protected with

linseed oil or clear varnish

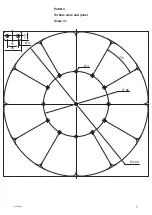

5.4 Function control

Check – that the windmill turns easily !

- that the mechanism between the turbine and the see –saw works freely.

- that the whole model will turn easily on its stand.

When everything has been checked it can be placed outside in an open space so that the wind can drive it.