16

E102894#1

6.6.2

Flying with power:

Wind the motor up 200 turns

Note:

If you use a Drehfix mechanical winder you will only need 100 turns, as it works at a ratio of 1:2!

Attatch the Drehfix to the propellor hub and turn If you wind it up by hand, you will need to tension the rubber

by holding the rear dowel away from the plane so that the propellor engages.

Then wind the propellor.

Hold the model level, give it a light push forward and let the propellor go.

The model should find its own flight pattern.

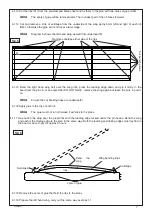

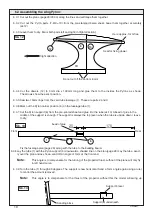

• If the model flies with an up and down motion the propellor angle must be altered by adding card between the

bearing and the end of the tube see Sk. 29

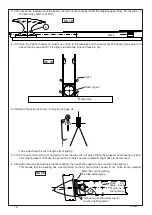

• If the model does not climb, decrease the bearing angle by adding card strips underneath between the ring

and the bearing.

• Add a further 50 turns to the motor and observe the flight pattern

A well lubricated motor should take 550 turns without breaking.

Note:

Remember if you use a mechanical winder, for every turn of the winder the rubber is turned

twice!!

Ratio 1:2

Have fun with your Dragonfly!

Entarging motor bearing angle

Desreasing motor bearing angle

Sk. 29

Summary of Contents for Dragonfly 102.894

Page 18: ...18 E102894 1...

Page 20: ...20 E102894 1...

Page 22: ...22 E102894 1...

Page 24: ...24 E102894 1...

Page 26: ...26 E102894 1...

Page 28: ...28 E102894 1...

Page 30: ...30 E102894 1...

Page 31: ...31 E102894 1 Fuselage 2 Scale 1 1...

Page 32: ...32 E102894 1...

Page 33: ...33 E102894 1 Fuselage 3 Scale 1 1 Top Bottom...

Page 34: ...34 E102894 1...