Wiring

7

Wiring

For connecting the sensor cables, observe the following basic conditions:

• Bring the sensor cable to the cable entry from underneath.

• Form a loop with the sensor cable close to the cable entry.

• Do not lay sensor cables in ducts of current-carrying lines.

• Observe cable specifications (see technical data).

• To lay sensor cables underground without protection is prohibited.

For connecting the sensor to the converter, a sensor cable is provided.

Connection to the

sensor

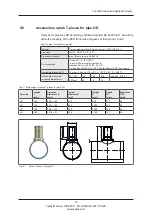

Fig. 15:

Connector

Tool

F

not needed

1. Loosen the connection cover of the sensor.

2. Loosen the plug cover on the sensor cable.

3. Insert the sensor cable until it audibly locks into place. Only then, the thread

grips.

4. Fasten the thread, until it locks into place. The connection is now fastened.

Fig. 16:

Connecting sensor cable

Notice!

Exact information about the connection of a sensor to a converter is given in the

instruction manual of the respective converter. There you can as well find the

corresponding wiring plans.

- 23 -

optek-Manual--1004-2011-02--AS56-US-2017-06-28

www.optek.com