Version 1.0.1 - 2020-07-23

21

Translation of original instruction

B20 | B25 | B32

EN

B20-

B25-

B32_

GB.

fm

The device must only be installed and operated in a dry and well-ventilated place.

Avoid places close to machines which cause chips or dust.

The installation site must be vibration-free, i.e. located away from presses, planing

machines, etc.

The substructure must be suitable for the drilling machine. Make sure that the floor has suf-

ficient load-bearing capacity and is level.

The ground must be prepared in a way that potential coolants cannot penetrate the floor.

Any parts sticking out such as stops, handles, etc. have to be secured by measures taken

by the customer if necessary in order to avoid endangering persons.

Provide sufficient space for the personnel preparing and operating the machine and trans-

porting the material.

Also make sure the machine is accessible for setting and maintenance works.

Provide for sufficient backlight (Minimum value: 500 Lux, measured at the tool tip). In the

event of a lower level of lighting, additional illumination must be provided, e.g. by means of

a separate workplace light.

CAUTION!

Arrange the machine's connection cable in such a way that it will not cause a tripping

hazard.

INFORMATION

The mains plug of the drilling machine must be freely accessible.

3.5

Assembly

WARNING!

Danger of crushing when assembling and installing the machine components.

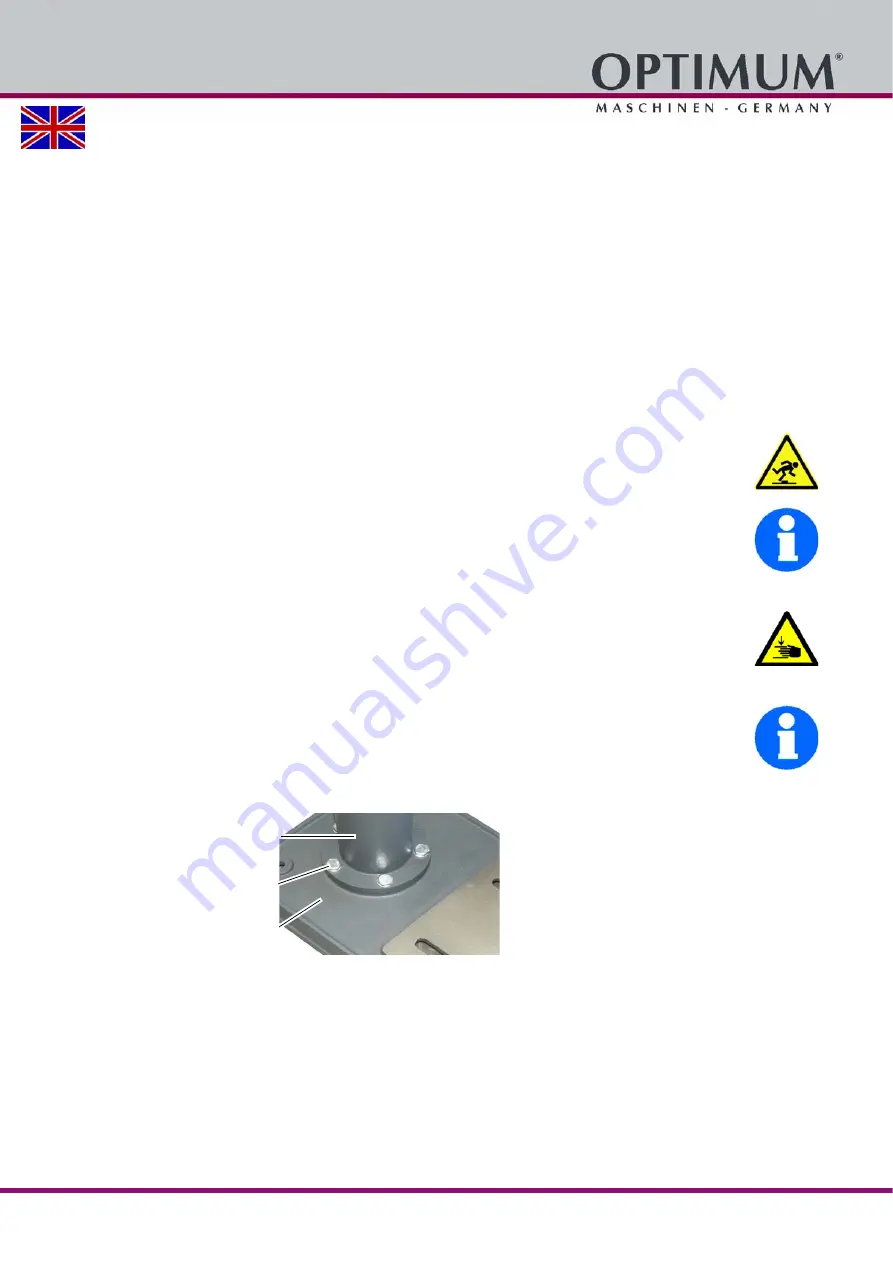

3.5.1

Mounting of base and drill column

INFORMATION

To mount the drilling machine, you will need a 17 mm hexagonal wrench and the hexagonal

screws supplied.

Put the stand on the floor and fix the drill column to the stand. Hexagon bolts are provided

to fix it.

Img.3-1: Stand

Drill column

Hexagon screws

Base