Version 1.0.1 - 2020-07-23

33

Translation of original instruction

B20 | B25 | B32

EN

B20-

B25-

B32_

GB.

fm

4.5

Drill chuck

Mounting Morse taper and drill chuck

A friction-locking connector holds and centres the drill chuck in the B16

holding fixture.

Check and clean the conical seat at the drill spindle and on drill

chuck.

Push the drill chuck with a firm jerk onto the B16 receptacle.

The drill chuck with MT taper is secured through a form-fit union (driver)

against twisting in the drilling spindle.

A frictionally engaged connection keeps and centres the drill chuck or

the drill in the drill spindle.

Check and, if necessary, clean the conical seat in the drilling spin-

dle and at the taper mandrel of the tool or the drill chuck.

Shift the morse taper with a firm jerk into the spindle sleeve.

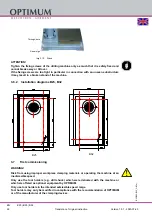

4.5.1

Function quick action drill chuck

The drill chuck consists of two parts (1 and 2).

Hold the upper part (1) of the drill chuck. With the bottom part of the drill chuck (2) it is pos-

sible to tighten or loosen the jaws of the drill chuck.

Turn the tool, drill (3) firmly.

Img.4-5: Quick-action drill chuck

ATTENTION!

Make sure that the clamped tool is firmly and correctly fitted.

1

2

3