Operation

Version 1.2.3 - 2021-11-02

81

Translation of original instruction

S275N | S275NV

EN

S275

N

_S275

NV_G

B_4.

fm

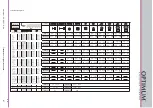

4.9.2

Saw belt speeds

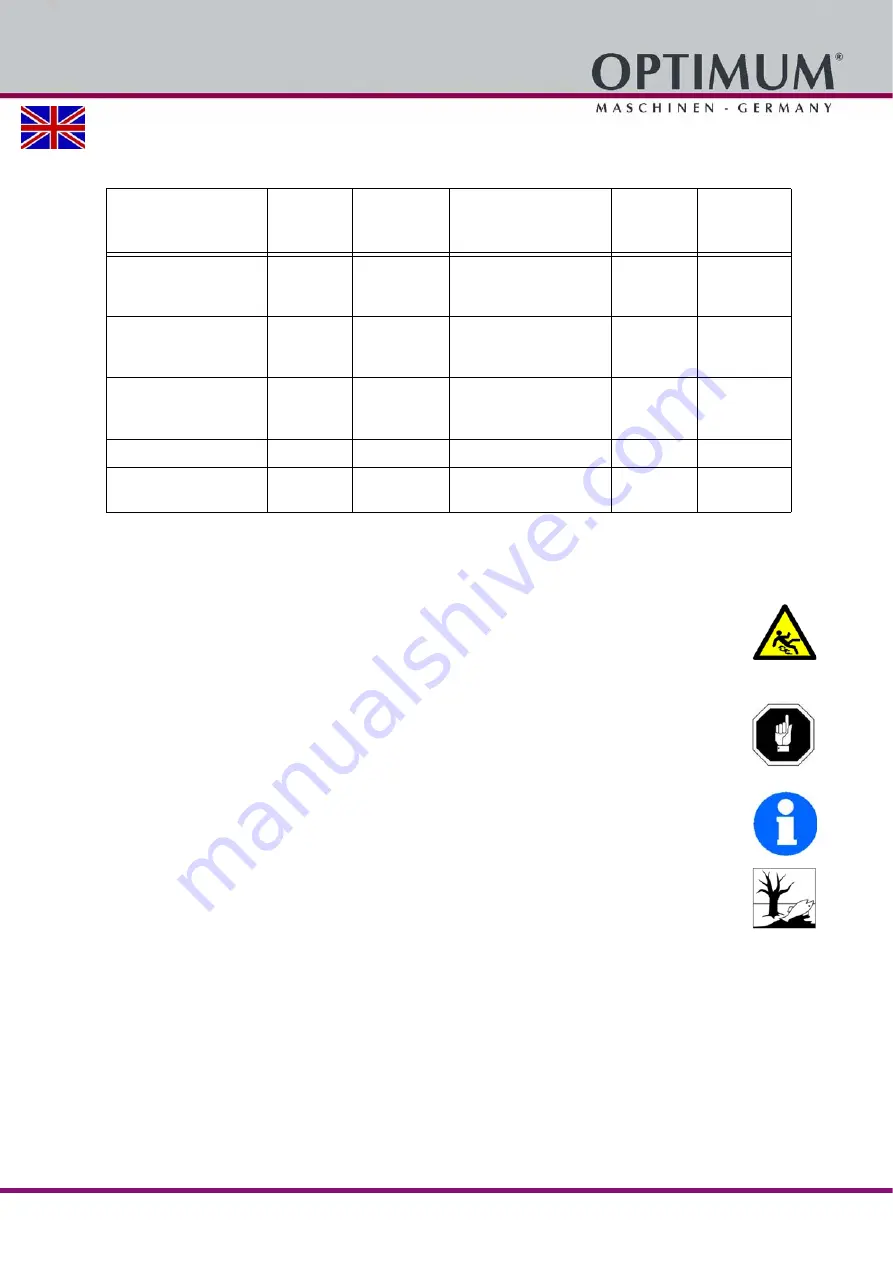

Guidelines values for cutting speeds [m / min]

:

General information concerning saw bands on page 83

4.10

Coolant equipment

WARNING!

Ejection of coolants and drainage of coolant over long workpieces on the floor. Make

sure you do not get the cooling lubricants on the floor. Spilled on the floor cooling

agents must be removed immediately.

ATTENTION!

Destruction of the pump due dry running. The pump is lubricated by the coolant. Do not

operate the pump without coolant.

INFORMATION

Use as cooling agents a water soluble, ecologically harmless sawing emulsion, which they can

refer in the specialized trade.

Make sure that the cooling agent is properly retrieved.

Respect the environment when disposing of lubricants and coolants.

Follow the manufacturer’s disposal instructions.

Switch on the cooling units by pressing the switch.

4.11

Starting the metal band saw

Start the metal band saw by pressing the green button.

Material

[m / min]

Feed

motion per

tooth [mm]

Material

[m / min]

Feed

motion per

tooth [mm]

C10, C15, St34, St37,

Steels up to 500 N/mm

2

30 - 50

0.03 - 0.06

Aluminium and alloy

aluminium

(solid material)

600 - 900

0.04 - 0.09

C20, C40, 15Cr3,

16MnC35,

Steels up to 800 N/mm

2

20 - 40

0.03 - 0.04

Aluminium and alloy

aluminium (profiles)

800 - 1200

0.03 - 0.07

38NCD4, 50CrV4,

Steels up to 1200 N/

mm

2

15 - 25

0.02 - 0.03

Bronze and Copper

200 - 300

0.04 - 0.06

Stainless steels

10 - 30

0.01 - 0.03

Brass

400 - 600

0.04 - 0.08

Cast iron

30 - 50

0.04 - 0.05

Synthetic

materials

60 - 150

0.04 - 0.08