OPTIMUM

M A S C H I N E N - G E R M A N Y

Assembly

Version 1.0.1 2014-05-16

Page 106

Original operating instructions

TU2506 | TU2506V | TU2807 | TU2807V

GB

3.6

First commissioning

ATTENTION!

Before commissioning the machine check all screws, fixtures resp. safety devices and

tighten up the screws if necessary!

WARNING!

When first commissioning the lathe by inexperienced staff you endanger people and the

machine.

We do not take any liability for damages caused by incorrectly performed commission-

ing.

3.6.1 Warming up the machine

ATTENTION!

If the lathe and in particular the lathe spindle is immediately operated at maximum load

when it is cold it may result in damages.

If the machine is cold such as e.g. directly after having transportation, the machine should be

warmed up for the first 30 minutes at a spindle speed of only 500 1/min.

3.6.2 Cleaning and lubricating

Remove the anti-corrosive agents on the lathe which had been applied for transportation

and storage. Therefore, we recommend you to use paraffin.

Do not use any solvents, cellulose thinner or any other cleaning agents which might affect

the coating of the lathe when cleaning the lathe. Observe the indications and notes of the

manufacturer for cleaning agents.

Oil all blank machine parts using an acid-free lubricating oil.

Grease the lathe according to the lubrication chart.

"Inspection and maintenance“ on page 146

3.6.3 Visual inspection

Check the oil level in the inspection glass of the feed gear.

Img.4-1: “Oil sight glass feed gear“ on page 146

3.6.4 Functional test

Check if all spindles are running smoothly.

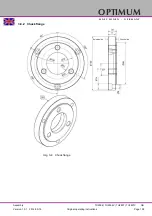

Check the state of the lathe chuck and the turning jaws.

3.6.5 Electrical connection

Connect the electrical supply cable.

Check the fusing (fuse) of your electrical supply according to the technical instructions

regarding the total connected power of the lathe.

ATTENTION!

For 400V machines: Imperatively make sure that all 3 phases ( L1, L2, L3) are correctly

connected.

Most motor defects result of wrong connections. For instance if a motor phase is not

correctly clamped or connected to the neutral conductor (N)..

Effects may be as follows:

The motor is getting hot very rapidly.

Increased motor noises.

The motor has no power.