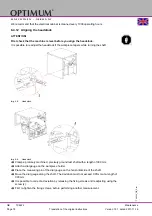

Ersatzteile - Spare parts

Version 1.0.1 2017-11-16

88

Originalbetriebsanleitung

TX6222

DE | EN

T

X

6222

_par

ts.

fm

OPTIMUM

M A S C H I N E N - G E R M A N Y

®

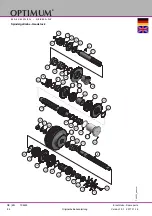

78

Scheibe

Washer

1

03432460178

79

Zahnrad

Gear

1

Z20

03432460179

80

Zahnrad

Gear

1

Z27

03432460180

81

Zahnrad

Gear

1

Z54

03432460181

82

Paßfeder

Fitting key

2

DIN 6885 - A 6 x 6 x 20

83

Sicherungsring

Retaining ring

2

DIN 471 - 32x1,5

84

Unterlegscheibe

Washer

1

DIN 125 - A 6,4

85

Stift

Pin

1

8x16

03432460185

86

Federstift

Spring pin

2

8x60

03432460186

87

Welle

Shaft

1

03432460187

88

Schalthebel

Switch lever

2

03432460188

89

Stahlkugel

Steel ball

4

03432460189

90

Feder

Spring

4

03432460190

91

Flansch

Flange

1

03432460191

92

Welle

Shaft

1

03432460192

93

Platte

Plate

1

03432460193

94

Zahnrad

Gear

1

03432460194

96

Zahnrad

Gear

1

03432460196

97

Stift

Pin

3

03432460197

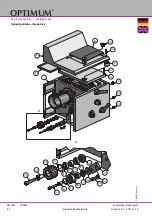

98

Flansch

Flange

1

03432460198

99

Platte

Plate

3

03432460199

100

Welle

Shaft

1

034324601100

101

Block

Block

1

034324601101

102

Flansch

Flange

1

034324601102

103

Welle

Shaft

1

034324601103

104

Platte

Plate

1

034324601104

105

Schalthebel

Switch lever

2

034324601105

106

Welle

Shaft

1

034324601106

107

Gabel

Fork

1

034324601107

108

Platte

Plate

1

034324601108

109

Gabel

Fork

1

034324601109

110

Welle

Shaft

1

034324601110

111

Exzenter

Eccentric

1

034324601111

112

Exzenter

Eccentric

1

034324601112

113

Gabel

Fork

1

034324601113

114

Flansch

Flange

1

034324601114

115

Flansch

Flange

1

034324601115

116

Flansch

Flange

1

034324601116

118

Flansch

Flange

1

034324601118

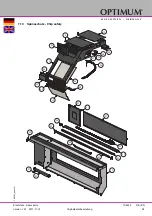

119

Verschlussschraube

Plug screw

2

034324601119

121

Fangblech

Baffle plate

1

034324601121

122

Abdeckung

Cover

1

034324601122

123

Buchse

Bushing

1

034324601123

124

Abdeckung

Cover

1

034324601124

125

Verschlussschraube

Plug screw

1

034324601125

126

Gummiplatte

Rubber plate

1

034324601126

127

Innensechskantschraube

Socket head screw

1

034324601127

128

Scheibe

Washer

1

034324601128

129

Zahnrad

Gear

1

034324601129

130

Kugellager

Ball bearing

2

6004

0406004R

131

Buchse

Bushing

1

034324601131

132

Sicherungsring

Retaining ring

1

DIN 472 - 42x1,75

133

Innensechskantschraube

Socket head screw

1

ISO 4762 - M14 x 70

134

Platte

Plate

1

034324601134

135

Rolle

Roll

1

034324601135

136

Buchse

Bushing

1

034324601136

137

Scheibe

Washer

1

034324601137

138

Scheibe

Washer

1

034324601138

139

Kugellager

Ball bearing

1

6202

0406202

140

Sicherungsring

Retaining ring

1

DIN 472 - 35x1,5

141

Innensechskantschraube

Socket head screw

1

ISO 4762 - M10 x 55

142

Innensechskantschraube

Socket head screw

1

ISO 4762 - M12 x 25

143

Scheibe

Washer

1

DIN 125 - A 13

145

Innensechskantschraube

Socket head screw

11

ISO 4762 - M8 x 16

146

O-Ring

O-Ring

1

034324601146

147

O-Ring

O-Ring

1

DIN 3771 - 31,5 x 2,65

148

O-Ring

O-Ring

3

DIN 3771 - 21,2 x 2,65

149

O-Ring

O-Ring

1

DIN 3771 - 40 x 3,55

150

Innensechskantschraube

Socket head screw

4

ISO 4762 - M6 x 10

151

Gewindestift

Grub screw

2

DIN 916 - M5 x 10

152

Innensechskantschraube

Socket head screw

4

ISO 4762 - M5 x 10

153

Ölschauglas

Oil sight glass

1

034324601153

154

Glas

Glass

1

034324601154

Ersatzteilliste Spindelgetriebe - Spare parts list headstock

Pos.

Bezeichnung

Designation

Menge

Grösse

Artikelnummer

Qty.

Size

Item no.