User Manual – ePX 200

OptiPro Systems, LLC.

Page 36 of 60

Last Modified: 7/30/2014

The Polishing Program Setup screen is the third screen in the new job setup sequence. This screen

consists of four independent polishing programs. Each program can be run individually or chained

together by toggling the checkbox under [Enable Cycle]. The grayed out boxes contain data that is

calculated based on the values that are entered in the other fields and cannot be interacted with. Many

of the fields such as Stroke Distance, Oscillations per Minute, and Bladder Pressure will be tweaked by

the technician as he or she gains experience. Most customers will do a runoff with a part they are

currently making at OptiPro prior to machine delivery. This provides an opportunity for OptiPro to fully

develop the tool set and tweak the process to the customer’s specifications. The two day training that

takes place during install sets a good baseline for the technician to follow for future jobs. The numbers

entered in the Stroke Distance, Oscillations per Minute, Bladder Pressure, Tool Speed and Speed Factor

in Figure 7-13 above are generally a safe place to start. OptiPro recommends one general guideline:

stroke distances beyond 3.00 mm are unnecessarily large and generally won’t help with figure

correction.

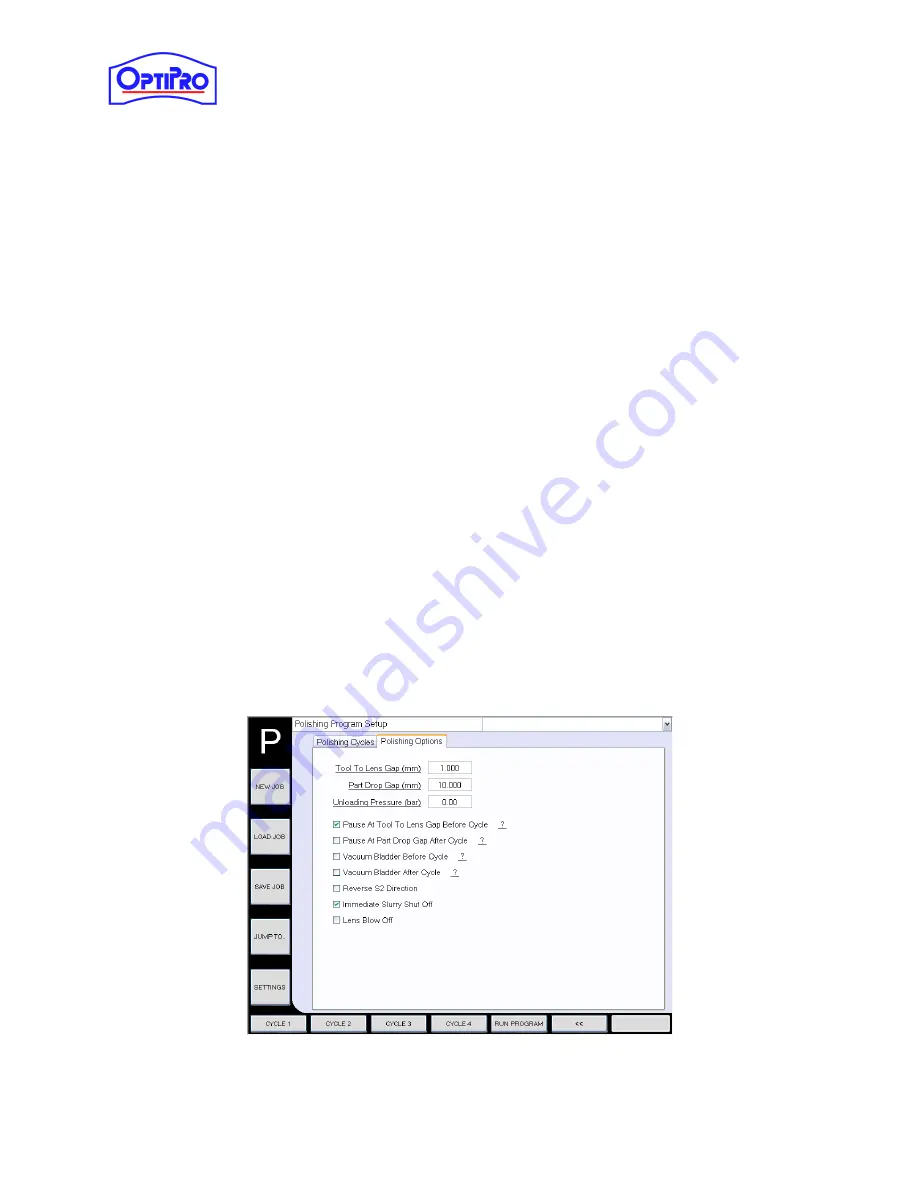

Tapping on the Polishing Options tab opens up the Options screen as seen in Figure 7-15. There is one

field in particular that is extremely important and cannot be overlooked. The [Tool to Lens Gap] field is

one of the most important fields in the software. A properly set tool to lens gap will ensure very good

quality optics. If the gap is set improperly, the quality of the finished optic will suffer and could even

increase the chance of a machine crash. The general rule of thumb with a new job is to set the gap at 1-

2mm and make sure the [Pause at tool to lens gap before cycle] checkbox is checked. These two actions

allow the technician to check the gap before the spindles start. The general rule of thumb here, the lens

should move about half of the sidewall thickness. Activating the bladder by stepping on the foot

activation switch will allow the technician to view the gap between the polisher and the lens. The

unloading pressure, which is usually set to 1 bar, provides air pressure when the foot switch is activated.

Figure 7-14: Job Menu Screen 3, Polishing Options