13

EN

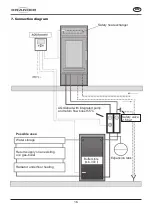

6. Connection of the water circuit to

the heating system

This fireplace with a water heat exchanger is

approved as a heat generator for hot water

heating systems with a permissible supply

temperature of up to 95°C.

Installation can be carried out on open or

closed systems. Comply with DIN 4751 and

EN 12828.

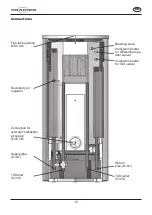

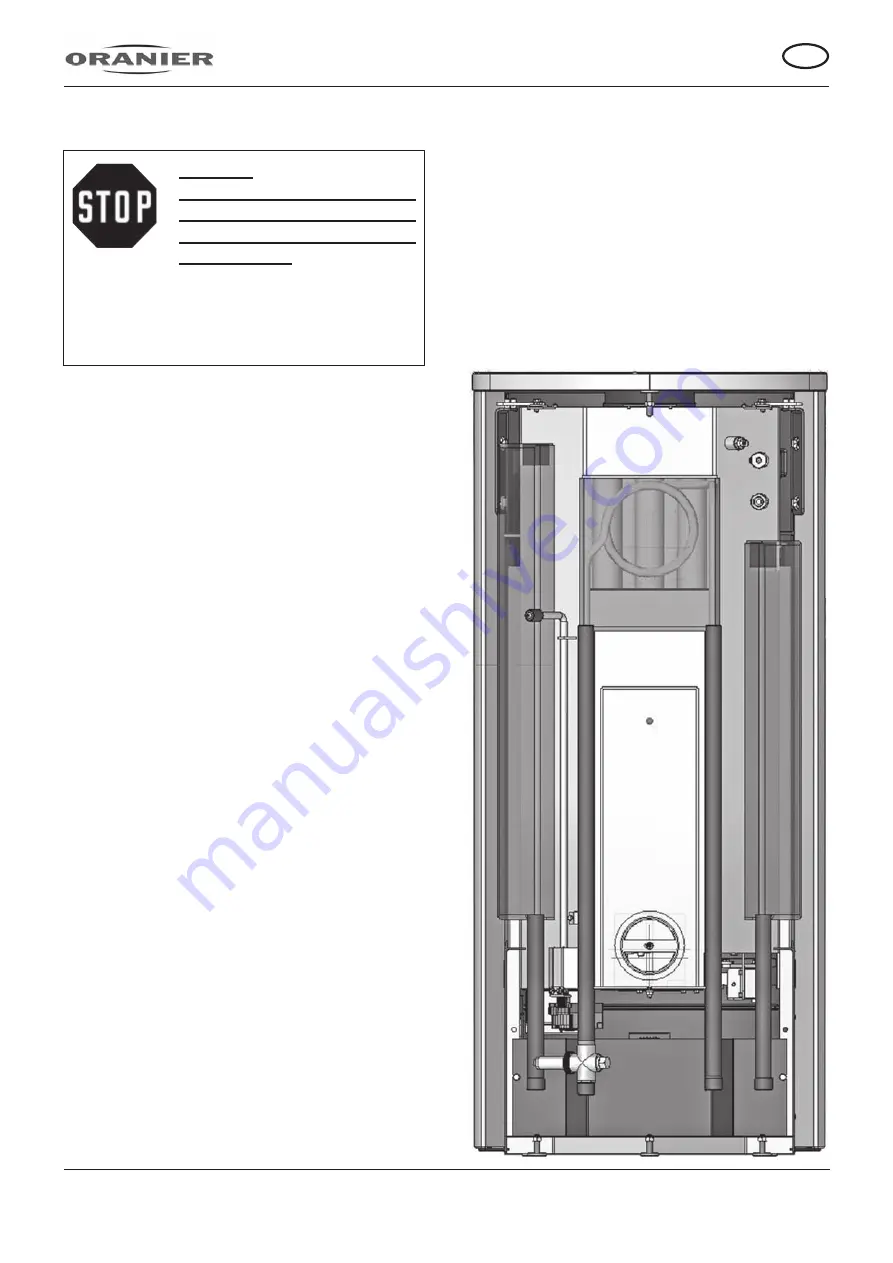

The pre-installation on the back of the firepla

-

ce includes supply and return pipes that have

already been pulled downwards, the heat ex-

changer with integrated thermal flow protec

-

tion, an immersion pocket for control sensors

and a filling and drainage valve.

The cover on the back can be removed for ins-

tallation and maintenance purposes.

All connections are clearly labelled for instal-

lation.

The function of the thermal safety valve

(TAS) must be checked at least once a year.

If required, the connection pipes can also be

routed straight down into the cellar, concealed

from the back wall.

The safety valve required (2.5 bar) must be

inserted

into the supply pipe

during installa-

tion.

There must be no option to shut off

the pipeline between the fireplace and the

safety valve!

On houses with controlled living room ventila-

tion, a short piece of connecting pipe, which is

available as an accessory for connecting an

external combustion air supply, may need to

be retrofitted.

Caution!

The heat exchanger must

only be connected to a hea

-

ting system by an authorised

professional!

All of the regulations, stan

-

dards and rules applicable

at the set-up location must

be complied with!

Summary of Contents for Polar Neo Aqua I

Page 20: ...20 Dimensions ...