21

MAINTENANCE INSTRUCTIONS

WALKING BELT CENTERING AND TENSION ADJUSTMENT

DO NOT OVERTIGHTEN the walking belt.

This may reduce motor performance and excessive roller wear.

TO CENTER WALKING BELT:

●

Place treadmill on a level surface

●

Run treadmill at approximately 3.5 mph

●

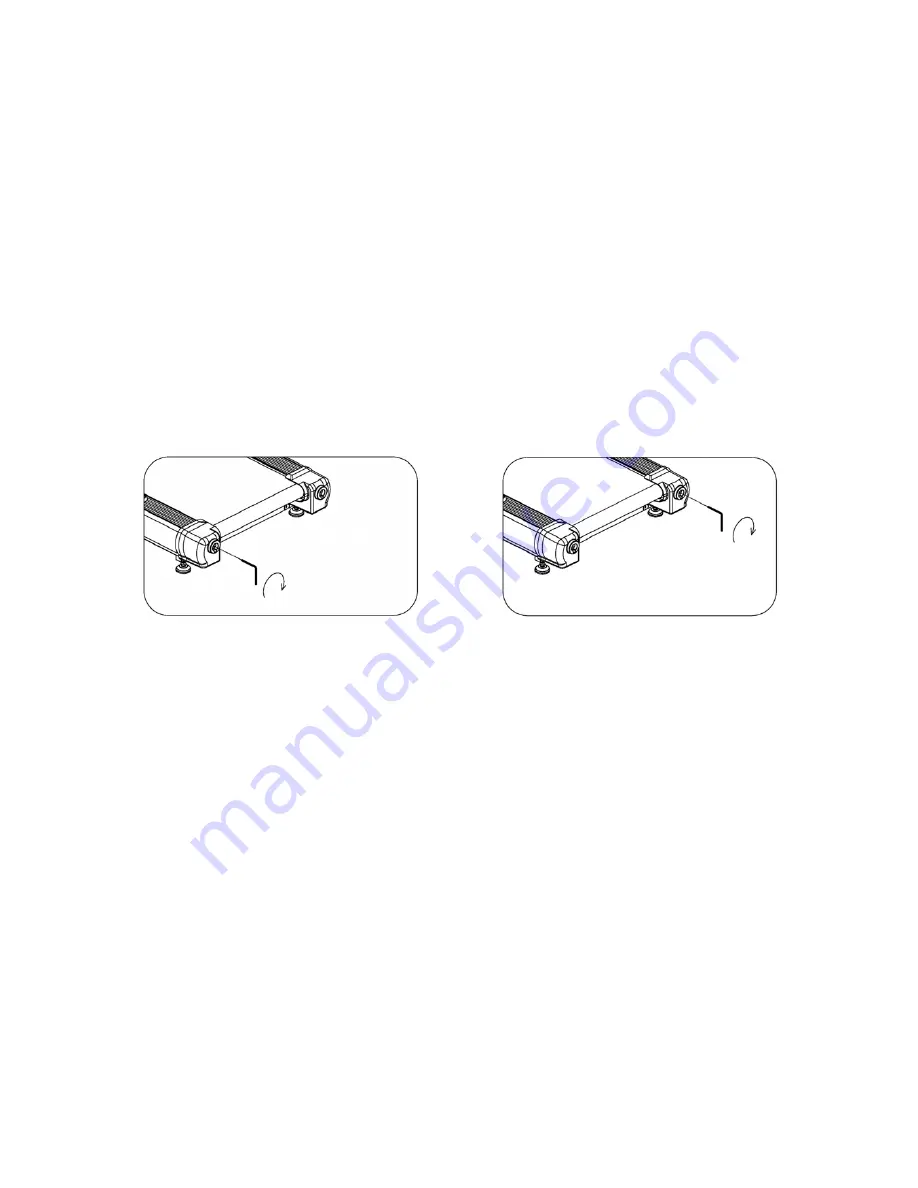

If the belt has drifted to the right, turn the right adjusting bolt 1/2 turn clockwise and the left adjusting bolt

1/2 turn counterclockwise

●

If the belt has drifted to the left, turn the left adjusting bolt 1/2 turn clockwise and the right adjusting bolt

1/2 turn counterclockwise

Picture A

: If the belt has drifted to the LEFT

Picture B

:

If the belt has drifted to the RIGHT

WARNING: ALWAYS UNPLUG THE TREADMILL FROM THE ELECTRICAL OUTLET BEFORE

CLEANING OR SERVICING THE UNIT.

CLEANING

General cleaning or the unit will greatly prolong the treadmill. Keep treadmill clean by dusting regularly. Be

sure to clean the exposed part of the deck on either side of the walking belt and also the side rails. This

reduces the build up of foreign material underneath the walking belt.

The top of the belt may be cleaned with a wet, soapy cloth. Be careful to keep liquid away from inside the

motorized treadmill frame or from underneath the belt.

Warning: Always unplug the treadmill from the electrical outlet before removing the motor cover. At

least once a year remove the motor cover and vacuum under the motor cover.

PIC A

PIC B