13

OPERATION

Mount the brush with the same countersink screws used for

mounting the driver plates.

•

NOTE: Tighten the screws sufficiently to avoid

disengagement of the brush from the machine during

operation.

To avoid stripping the screws do not over tighten. An electric

screwdriver with a clutch will ensure that stripping will not

occur.

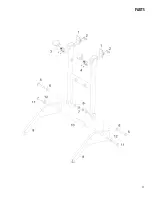

Attaching and Removing the Driver Plates

Put the machine base in an upright position, sitting on the

foot of the bumper. Remove the driver plate by removing the

four countersink screws in the center of the plate using an

electric screwdriver.

Attach a driver plate to the machine base by lining up the

holes of the driver plate with the appropriate threads of the

bearing retainer ring. It is recommended to align the threads

of the bearing horizontally to the ground.

Put the four countersink screws through the holes of the

driver plate and first screw them into the bearing retainer

ring threads manually. Then, tighten the screws with an

electric screwdriver

•

NOTE: Tighten the screws sufficiently to avoid

disengagement of the driver plate from the machine base

during operation.To avoid stripping the screws do not

over tighten. An electric screwdriver with a clutch will

ensure that stripping will not occur.

ACCESSORIES AND APPLICATIONS

WARNING

Never store the accessories in wet conditions. Keep the

accessories away from extreme heat and from chemicals.

Summary of Contents for SPRAYBORG

Page 1: ...OPERATING MANUAL ENG V052015 ...

Page 19: ...19 PARTS ...

Page 21: ...21 PARTS ...

Page 23: ...23 PARTS ...

Page 25: ...25 PARTS 1 2 ...

Page 27: ...27 PARTS ...

Page 29: ...29 PARTS ...

Page 31: ...31 PARTS 13 ...

Page 33: ...33 PARTS 2 1 ...

Page 35: ...35 PARTS ...

Page 37: ...37 PARTS ...

Page 39: ...39 NOTES ...