11

Fitting and maintenance instructions HRC 300/400 4B(P/RH)

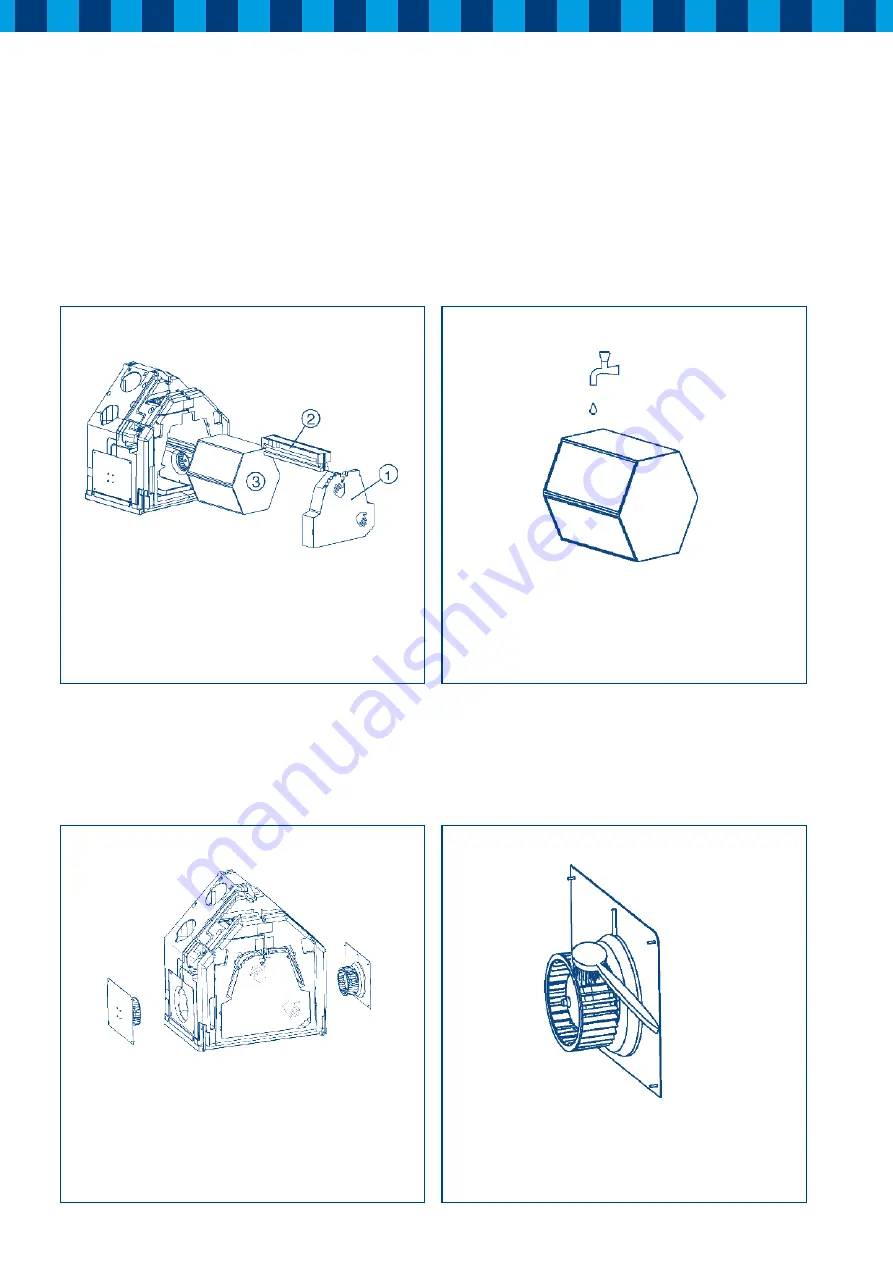

4.2 Installer maintenance

Take out the heat exchanger

(once every 3 years)

3

•

Disconnect the power supply

•

Pull the inner-assembly out of the frame

•

Disconnect the wiring to the motor from the pcb

•

Unscrew the 4 screws of the motor plate

•

Take off the fan

4

•

Clean the fan with a dry stiff brush

•

Prevent damage to the fan blades

•

Do not use water for cleaning

2

•

Clean the heat-exchanger with warm water and a mild

detergent.

•

Rinse with warm water

1

•

Switch off the power supply and remove the cover

•

Remove the bypass cover (1)

•

Remove the press tray (2)

•

Remove the heat-exchanger (3)

Clean the fans

(if dirty)

The fans must be cleaned if they are dirty. Be sure not to bend the fan blades; this could cause a motor imbalance, unnecessary noise

and will shorten the life of the motor bearings.