14

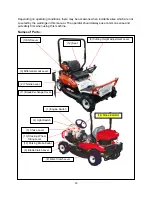

Working of Each Part:

(1) Engine Switch

Insert for the key, and operates [START], [RUN], and [OFF].

(2) Throttle Lever

Adjusts the engine speed by [LOW] - [HIGH].

(3) Choke Lever

Used to start the engine during cold weather. [CLOSE] position by pulling, and [OPEN]

position by putting back. This operation is not necessary when the engine is warm.

(4) Light Switch

Pressing the switch once: [ON]; and pressing the switch again: [OFF]. The switch turns

blue when the light is [ON].

This light is for driving only. Do not use it for operation. It may cause a risk of falling if

the operator suddenly enters dangerous surroundings. Drive at a slow speed when the

light is turned on.

(5) Cutting Height Adjustment Lever

This machine can be set to any height between 3.1” (80mm) and 6.3” (160mm). Press

the cutting height lock button with your thumb at the tip of the adjustment lever. Move the

lever to the height of your choice and release the button to set the height. Use the label

on the right of the position lever as a guide when adjusting the cutting height (shown in

1inch increments).

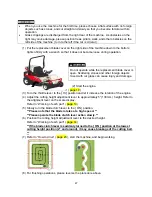

◇◇

When the cutting height adjustment lever is NOT all the way up, the engine

will not start

◇◇

The height of the knife blade when the knife is rotating is different than when the knife

has stopped (the knife is lifted because of high speed centrifugal force). The scale is the

number of knife rotations. Please be aware of the actual cutting height as you work.