25

■

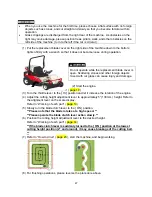

How to load and unload:

Ramp Standards

:

Make sure that your ramp is comprised of materials strong enough to conform to the following

standards.

Length: 3.5 times longer than the truck’s loading bed is high. (Less than 15 ° tilt angle

of the bridge)

Width: At least as wide as the wheel span of the machine

Strength: Sufficiently strong enough to take the total weight of the machine and the

operator combined.

Surface: Use a ramp with a non-slip surface.

Do not stop in the middle of the ramp. Especially when restarting the machine upon

loading, there is a danger of the machine’s front tires lifting up off the ground. Please

load and unload at a low speed.

Please use a truck without a canopy over the bed. When unloading, the operators may

collide with the canopy.

Park the machine on a flat and stable surface, and don’t load and unload on a

highway.

Please use a truck that can bear the total weight of the diver and the weight of the

machine.

To prevent accidents, please arrange pre-determined signals with the truck driver, if

you work with more than one person.

Loading and unloading at night is dangerous. If this is unavoidable, choose a location

that has adequate lighting. If it is hard to see the position between the ramp and the

tire there is a danger of falling.

Turn off the truck’s engine, pull the emergency brake to “on,” and put a wheel chock

under the tire.

The cutting height adjustment lever must be all the way in the up position. There is a

risk of falling if the ramp makes contact with the knife.

The differential lock lever must be in the [ ON ] position. Do not operate the

differential lock on the ramp.

Attach the ramp’s hook so that there are no obstructions where it attaches to the

truck’s loading bed. Also make sure that the ramp is securely attached.

Make sure that the tires on either side of the machine are positioned in the center of

the ramp.

Stop the engine on the carrier, turn the fuel valve to the [ CLOSED ] position, and

remove the ignition key.

Use a

strap that is strong enough to be fixed from the machine and securely to the

carrier.

(1) Load in forward and unload in reverse.

(2) Attach a ramp which conforms to the standards below.

(3) Put the differential lock lever in the [ ON ] position and the cutting height adjustment

lever in the [ MOVE ] position. Do not use any other positions.

(4) Put the throttle lever in the intermediate position between [ HI ] and [ LOW ]. Always put

the drive clutch lever in the [ ON ] position.

NOTICE