43

Tightening torque of hard lock nut is “800kgf

・

cm” (78.4N

・

m).

As a rule, tighten force of approx. 70.5lb (32kg) or more with a 30cm box wrench (size

22).

For increasing torque, a torque wrench is needed. It is recommended that you check

with the dealer in advance to how much force or tightening the torque needs.

More frequent inspection of the blades is necessary if using the machine on areas

including dry earth and sand which cause faster wear and tear of the blades.

We recommend purchasing a spare set of blades in advance and keeping them close at

hand.

When replacing the blades, be careful not to lose the blade ring collar.

◇◇

You will know

it is time to replace the blade(s) if the gauge (hollow) at the back of the

blade mounting bolt is worn.

◇◇

How to fix the blades:

Please be aware that, once repaired, blades will not perform as when unit was initially

purchased.

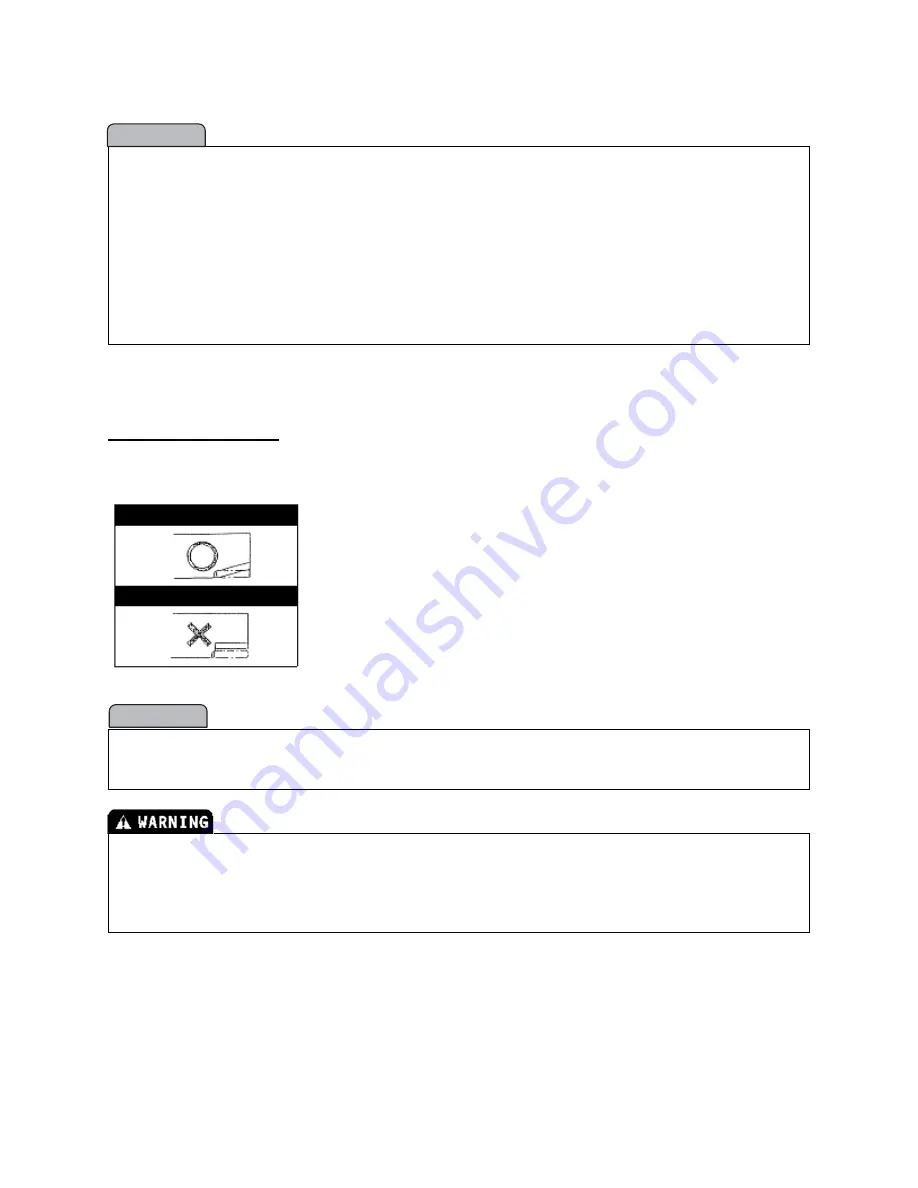

1. Sharpen the blade as follows:

When you polish the blade, hold the blade firmly.

If the blade is sharpened parallel to the original

blade, it will cause damage.

Please sharpen as shown at left

To keep the balance of the blades, sharpen each

blade uniformly

2. Keep a flat surface of approx. 0.015” ~ 0.024” (0.4~0.6mm)

on the cutting edge. If the blade is sharpened like a razor

blade, it will wear out and become blunt quickly.

When polishing with a grinder, apply water and avoid raising the temperature of the

blade, and polish gradually.

If the blade temperature is too high, the blade will retain heat and wear down sooner.

Do not work in places where there are hazards such as flammable fuel and batteries.

When using a grinder, always wear a hat, thick gloves, and security glasses. Always fix

the entire blade, not just certain sections. ( Partial fix is prohibited! )

If both blades are not balanced, it causes abnormal vibration, and the machine may be

damaged.

NOTICE

NOTICE