25

Oiled Parts Inspection, Replacement, and Lubrication

This machine is shipped WITH

GEAR OIL. However, please check if it’s lubricated with the

described oil, in the described parts, and in the described quantities before use. Low oil level

can cause machine damage. This type of damage is not covered by manufacture warranty.

To always operate this machine in good condition, perform oil changes as recommended.

When performing inspection, replacement, or lubrication of oiled parts, place the machine on a

flat, open surface. Switch on the engine and warm it up to confirm it is working properly. Then

switch off the engine, allow it to cool down and remove the spark plug cord.

After switching off, please wait at least 5 minutes for all parts to cool down before you touch the

machine. Immediately after the engine has stopped, the body will be very hot and can cause

burns if touched.

After switching off the engine, oil will still be in the engine and transmission so the quantity of oil

remaining will not be exactly displayed.

After changing the oil, please dispose of waste oil in accordance with local laws and regulations .

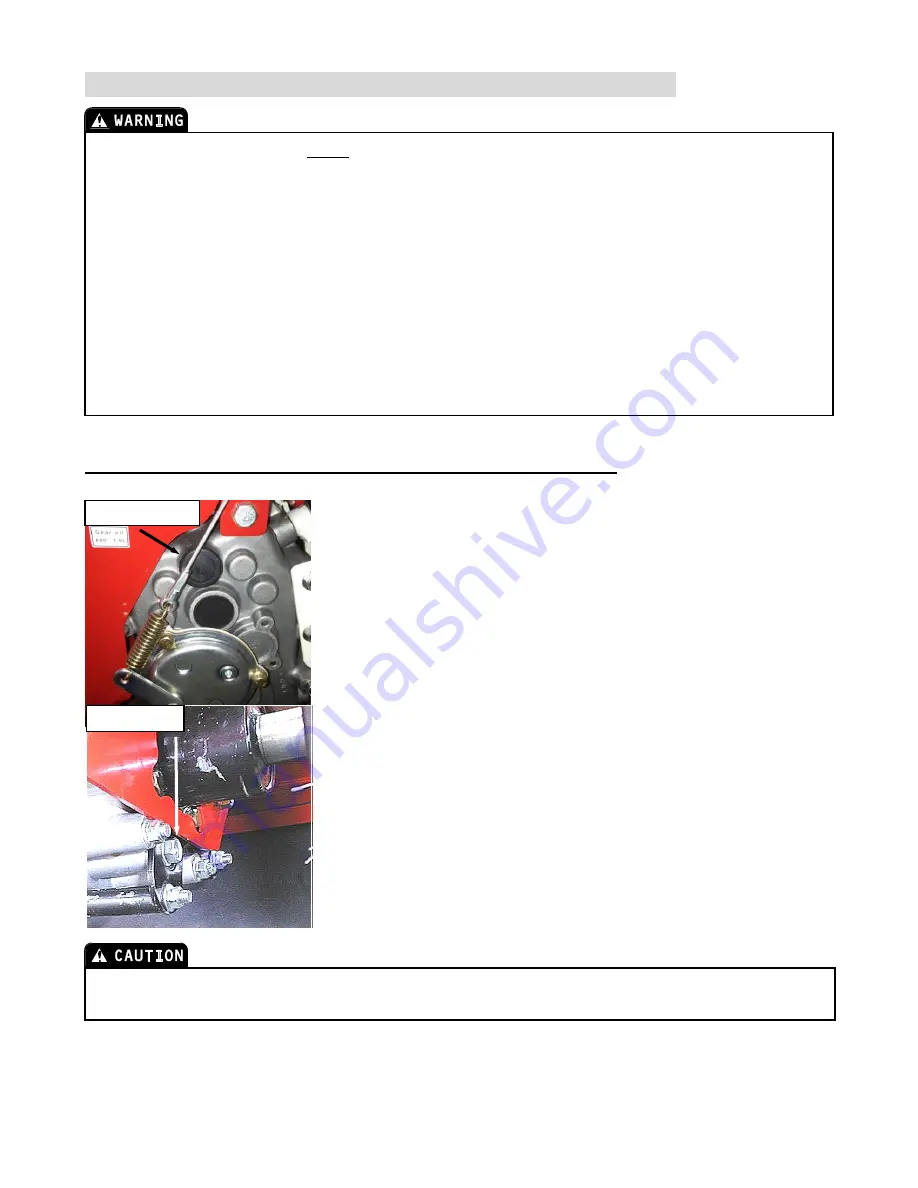

Transmission oil lubrication, inspection, and replacement

Inspection

Remove the oil inlet plug from the upper part of the transmission case on

the left side of the transmission, and check oil.

Check that the oil is fill to the inlet opening, if so, the oil is at the correct

level.

Replacement/Lubrication

Prepare a suitable container for removed oil. Replace oil after the first

20

hours

of operation and roughly every 100 hours thereafter by removing

the drain plug from the bottom left side of the transmission case.

After reattaching the drain plug, fill with 1.7 US qt (1.6L) of transmission

oil (SAE 90 or SAE 80W -90) by pouring through the oil inlet.

After putting in oil, be sure to properly reattach the oil inlet plug to avoid any leakages.

Make sure the drain plug gasket contacts the mounting surface and then turn it 3/4 of a rotation.

Oil inlet plug

Drain plug