29

How to inspect the fuel lines

When inspecting the fuel line, be absolutely sure not to be in the presence of lit tobacco, naked

flame, or other sources of ignition. These can cause fire and explosions.

How to clean the fuel valve

When cleaning the fuel valve, be absolutely sure not to be in the presence of lit tobacco, naked flame,

or other sources of ignition. These can cause fire and explosions.

Do not wash with highly flammable substances such as gasoline or thinner.

Clean inside the fuel valve after every 50 hours of operation.

Perform this work in a clean place free from dust and dirt. Accidents can be caused if dust and d irt

enter the machine.

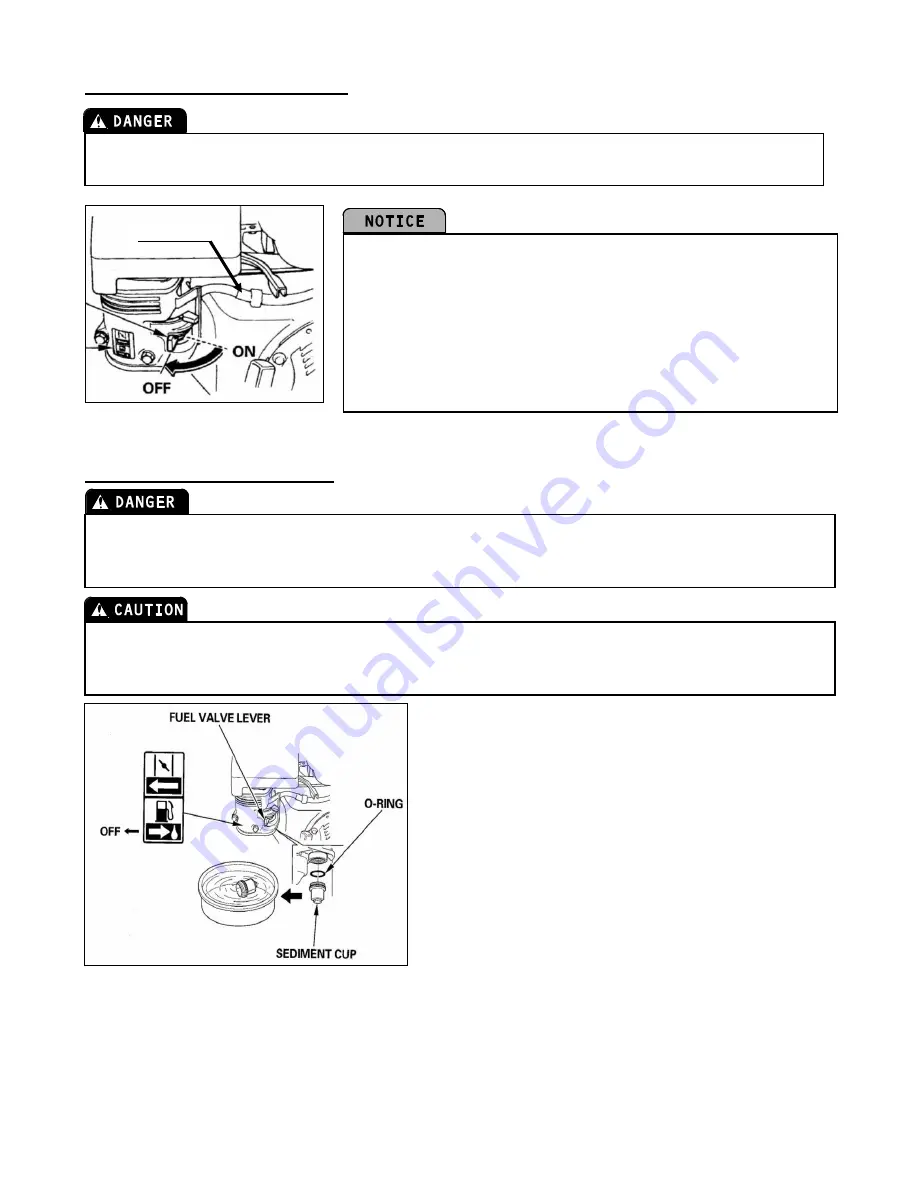

1.

Move the fuel valve to the OFF position, and

then remove the fuel sediment cup and O-ring.

2.

Wash the sediment cup in non-flammable

solvent, and dry it thoroughly.

3.

Place the O-ring in the fuel valve, and install the

sediment cup.Tighten the sediment cup securely.

4.

Move the fuel valve to the ON position, and

check for leaks.Replace the O-ring if there is any

leakage.

The rubber parts of the fuel pipe will deteriorate even if you do

not use the machine. Change the attaching b ands together with

new fuel line parts every 3 years or immediately if they have

split.

Always take care that the fuel line and fastening bands do not

become loose or split.

When changing the fuel line, be sure there is no dust or dirt

inside.

Fuel pipe