30

How to inspect and adjust the spark plug

1.

Remove the spark plug with a plug wrench and clean away

any carbon deposits on the electrode (A) with a wire brush

and wipe away any moisture if present.

2.

Replace the spark plug with a new one if the ceramic part

has cracked or the electrode have suffered extensive wear

and tear.

3.

Please adjust the spark plug electrode clearanc e (B) to

0.028-0.031in (0.7-0.8mm).

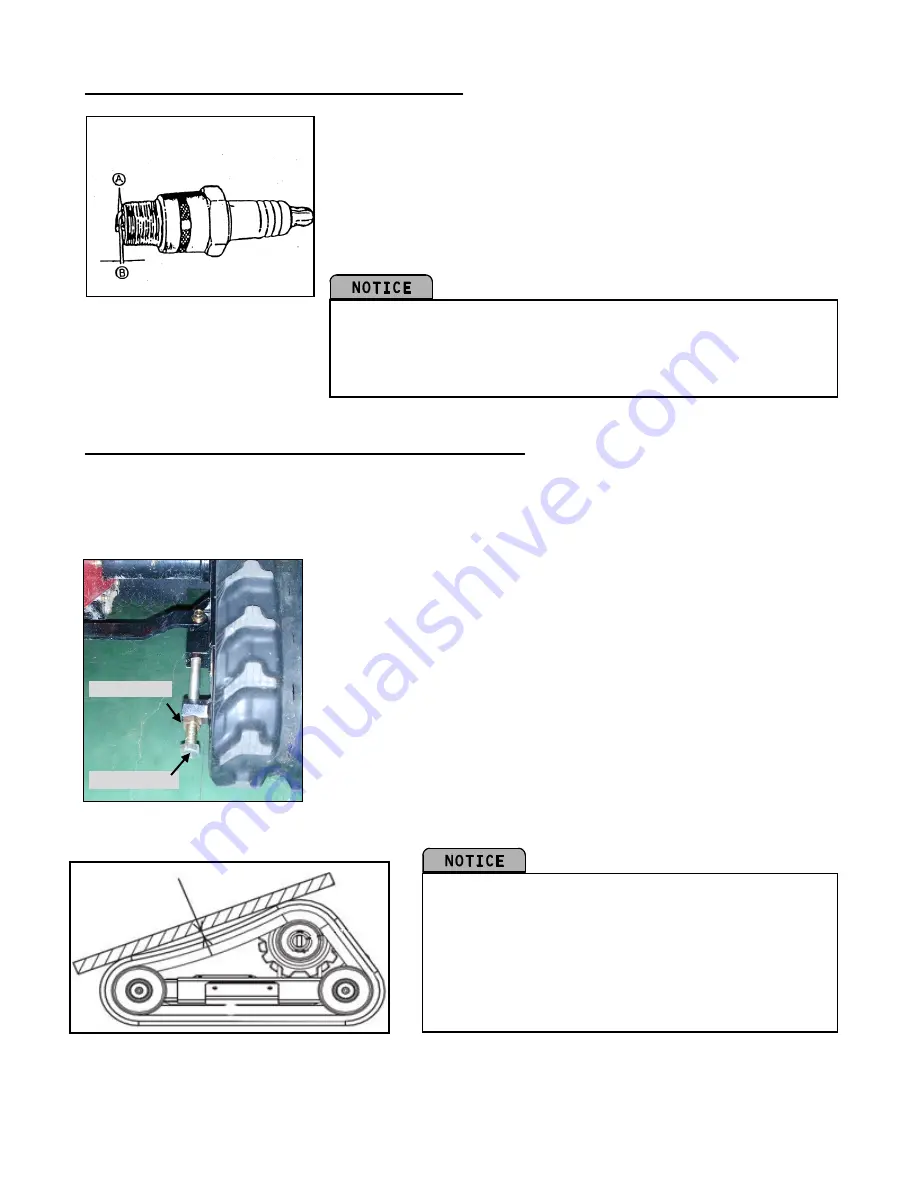

How

to adjust the tension on the crawler tracks

New crawler track parts will stretch and become loose after a period of use, as they become

acquainted with the sprocket. If the crawler tracks are not adjusted to th e correct tension, they can

slip off during operation and their lifespan can decrease. Follow the steps below to adjust crawler

track tension.

1.

Loosen the crawler track tensioning bolt’s lock nut, located at the

rear of the machine.

2.

Turn the crawler track tensioning bolt to tighten it.

3.

Adjust tension so that there is a clearance of 5/8in to 3/4 in along

line [A] when you push down on the crawler track .

4.

Adjust the left and right crawler tracks so that equal tension is

placed on them.

5.

Securely tighten the lock nut after adjusting.

When attaching a spark plug onto the engine, screw by hand at

first before tightening with a plug wrench. If you start by using a

plug wrench to screw in the spark plug, there is a danger of

cross-threading it. (Refer to spark plug standards, page 33.)

As there is an initial lengthening of new belts and

wires, please readjust after 2-3 hours of use.

Check for strange noises and overheating when you

move the machine.

Avoid strenuous work for the first 2 -3 hours, to allow

all parts sufficient time to break-in.

Please perform recommended maintenance and

periodic inspections after use.

Tension

b

olt

Lock nut

A