42

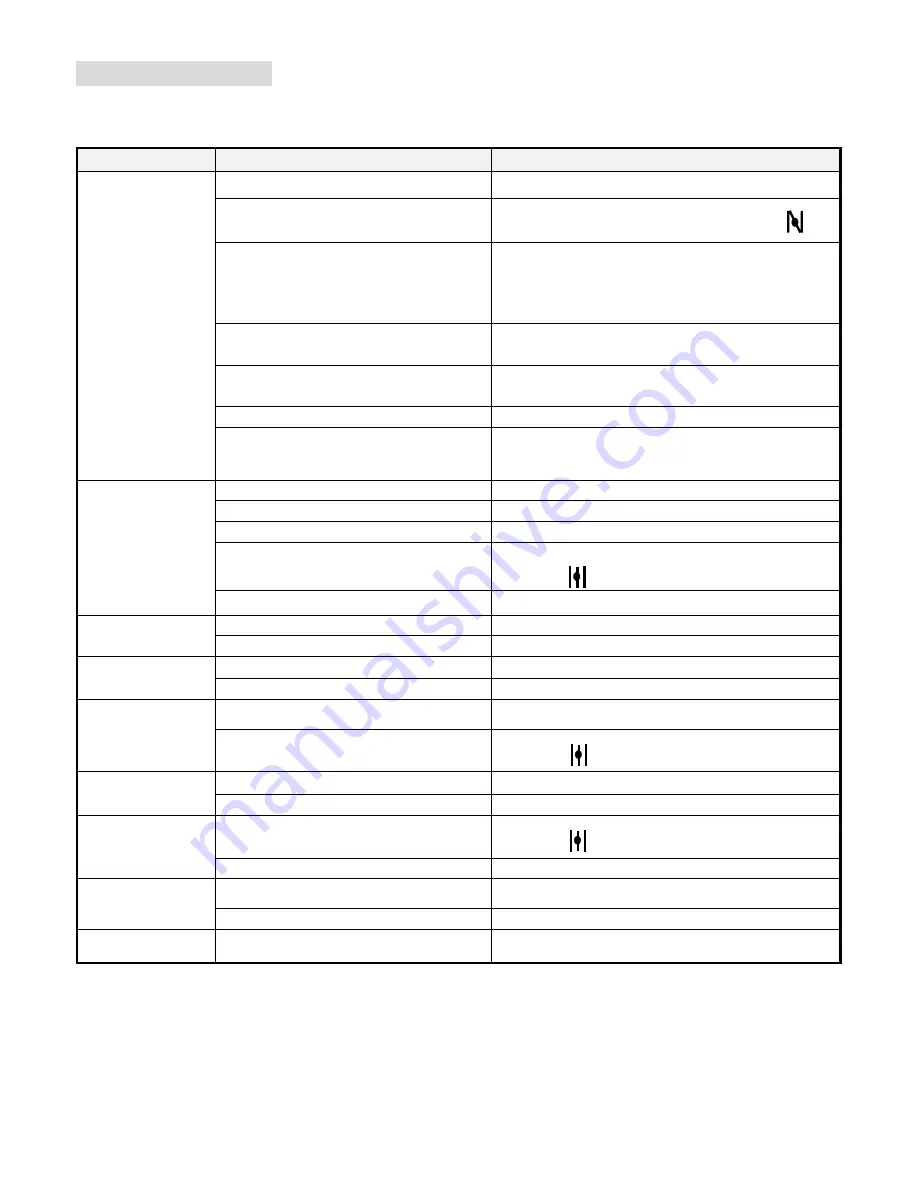

Troubleshooting

If the engine malfunctions perform diagnosis by referring to the following table and then taking the appropriate

action.

Effect

Possible cause

Treatment

You have trouble

starting the

machine, or the

machine will not

start at all.

Safety switch is not in the [start up] position.

Put the safety switch to the [start up] position.

Choke lever has not been pulled out.

When cooling the engine, put the choke bar in the

position.

Fuel is not flowing properly.

Inspect fuel tank, remove impure deposits or water.

Remove the fuel valve strainer and clean out any

sediment deposited inside the cap along with any other

attached dirt.

There is air or water mixed in the fuel

delivery system.

Remove foreign object, inspect fastening bands, replace

damaged parts with new ones.

In cold weather, oil becomes thick, and so

the rotation of the engine heavy.

Use the correct oil depending on the outside temperature.

Ignition coil or unit is defective.

Replace the ignition coil or unit.

Defective spark plug.

Inspect the gap between spark plug electrodes and

adjust.

Replace with new spark plug.

Output shortage

Fuel shortage.

Refuel the machine.

Clogged air filter.

Clean the element.

Poor quality fuel.

Replace with good quality fuel.

Choke has not been fully opened.

Return the choke bar completely.

Put it in the

position.

Cooling system is clogged.

Clean around the recoil starter.

The machine stops

suddenly.

Fuel shortage.

Refuel the machine.

Fuel valve is closed.

Open the fuel valve.

Exhaust gas is

abnormally black

Poor quality fuel.

Replace with good quality fuel.

Overfilled with engine oil.

See that oil level is straight.

Muffler emits black

smoke and power

output falls.

Air filter element is clogged.

Clean the element.

Choke has not been fully opened.

Return the choke bar completely.

Put it in the

position.

Muffler emits gray

smoke.

Overfilled with engine oil.

Check that oil level is straight.

Cylinder or piston ring is worn out

Replace the ring.

Engine power is

not stable (does

not increase).

Choke has not been fully opened.

Return the choke bar completely.

Put it in the position

Poor quality fuel.

Replace with good quality fuel.

Momentary stall.

Defective ignition coil.

Replace the ignition coil.

Fuel filter is clogged.

Clean the fuel filter.

Exhaust has an

abnormal odor.

Poor quality fuel.

Replace with good quality fuel.

If you do not understand any of these points, please consult with the retailer where you purchased this machine.