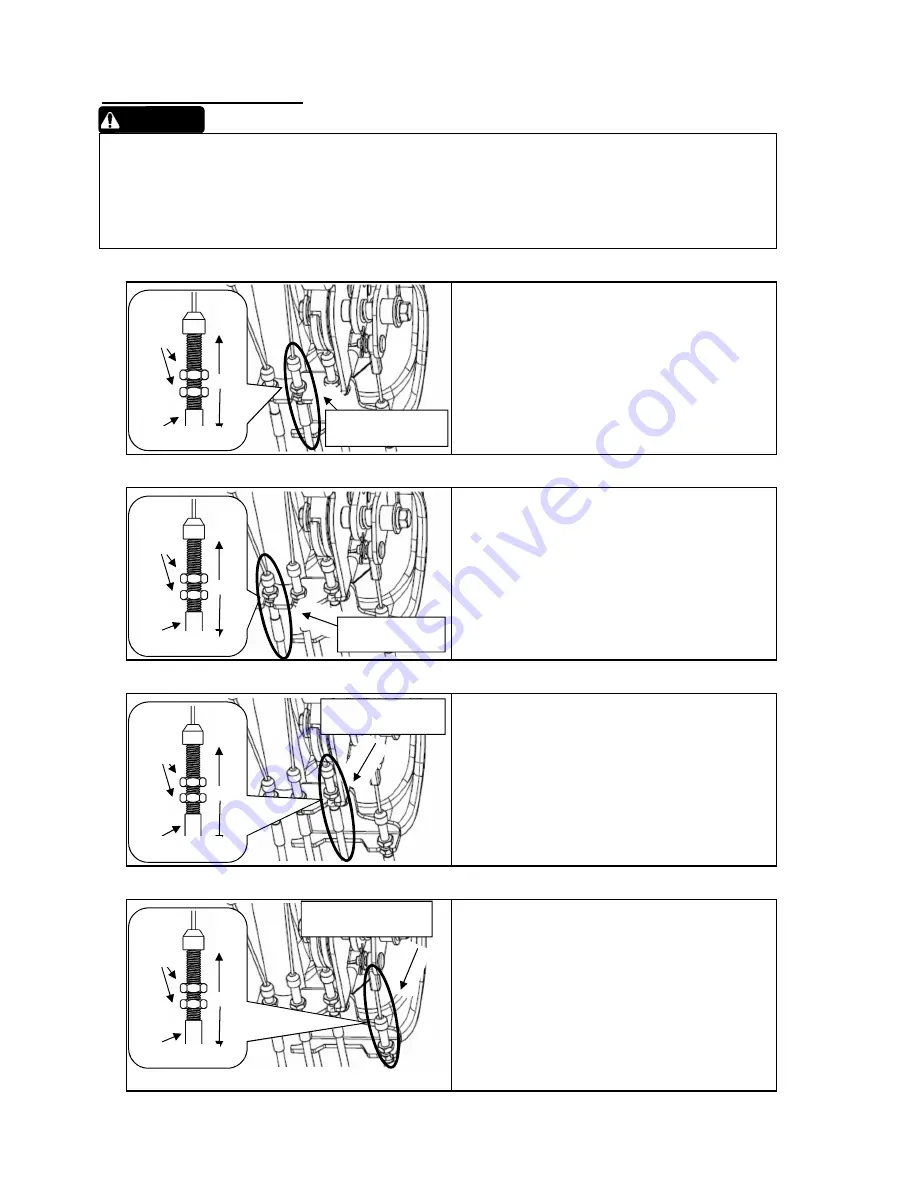

5) Adjusting each wire

●

Check that you are taking sufficient safety precautions when adjusting each type of wire by

placing the machine on a flat, open surface with the engine switched off and the spark plug cord

removed.

●

Please verify that the machine moves properly after the adjustment.

●

If operation does not improve after adjustment, please contact the dealer where you

purchased the machine.

■

Blade control wire

Push the Blade safety lock and then pull

back the Blade control lever (pg. 20).

1.

If the spring that connects the blade control wire

and the Blade control lever does not extend:

Move the Adjuster towards [B]

2.

If the spring that connects the Blade control

wire and the Blade control lever is not slack:

Move the Adjuster towards [A]

■

Drive clutch wire

Push the Driving clutch lever forward, hold

with the handle and then pull the machine

back. Make sure the wheels are locked.

1.

If the wheels do not lock when you pull the lever,

or unlock when stress is put on the machine:

Move the Adjuster towards [B]

2.

If the wheels lock even when you release the drive

clutch lever or the unit does not stop properly:

Move the Adjuster towards [A]

■

Throttle wire

Slide the Throttle lever up to the choke

position and then back to the [HI] position.

1.

If it does NOT push the choke arm enough:

Move the Adjuster towards [B]

2.

If it pushes the Choke arm while in the [HI]

position:

Move the Adjuster towards [A]

■

Speed change wire

Make sure the wheels are locked when you

hold the handle with Driving clutch lever at

each speed position.

1.

If the wheels do not lock on 3rd speed(gear)

the speed is slow even at maximum speed(hst):

Move the Adjuster towards [B]

2.

If the wheels do not lock on 1st speed or the

change lever cannot be moved to 3rd speed(gear)

you are traveling at a minimum speed(hst):

Move the Adjuster towards [A]

WARNING

A

B

ADJUSTER

LOCK

NUTS

(M6)

BLADE CONTROL

WIRE

A

B

A

B

A

B

DRIVE CLUTCH

WIRE

THROTTLE WIRE

SPEED CHANGE

WIRE

LOCK

NUTS

(M6)

ADJUSTER

LOCK

NUTS

(M6)

ADJUSTER

LOCK

NUTS

(M6)

ADJUSTER

27