1, For Safe Operation

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1) Warning labels

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2) Important safety points

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

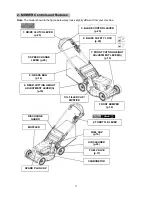

2, MOWER Controls and Features

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3, How to Assemble Machine

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4, Before Operation

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5, How to Operate

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1) How to start and stop the engine

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2) Operating the contorols for mowing

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

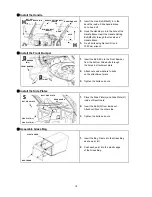

6, Parts Inspection and Repair

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1) Oiled Parts Inspection, Replacement, and Lubrication

・・・・・・・・・・・・・・・・

2) Cleaning the air filter

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3) Checking and adjusting the spark plug

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4) Spark Arrester (optional equipment)

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5) Adjusting each wire

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6) Inspecting and replacing blades

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7, Regarding Long-term Storage

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8, Specifications

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9, Consumable Parts List

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10, Optional Equipment

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11, Periodic Voluntary Inspection Table

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12, Self Diagnosis Table

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13, Troubleshooting

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

14, LIMITED WARRANTY

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

22

30

Contents

25

15

17

17

19

34

31

26

33

4

4

5

11

13

22

35

27

28

26

29

30

30

3